(1)Mig welding machine

This method is popular in various industries due to its versatility, speed, and ease of use .Advantages of CO2 Welding Speed and Efficiency: CO2 welding allows for high welding speeds, making it suitable for large production runs. Versatile Applications: It can be used on a variety of materials, including steel, aluminum, and stainless steel, making it adaptable for different projects .Ease of Use

Proper surface preparation is crucial for achieving strong welds .Setup: Assemble the welding machine, attach the gas supply, and adjust the settings based on the material thickness and type. Welding: Initiate the arc by pulling the trigger on the welding gun.

The wire electrode melts and fuses with the base metal, while the CO2 gas provides a protective atmosphere to prevent oxidation .Cooling and Inspection: After completing the weld, allow it to cool and inspect for any defects or inconsistencies.

Applications of CO2 WeldingCO2 welding is widely used in various sectors, including :Automotive: For assembling vehicle frames and components .Manufacturing: In the production of machinery and equipment .

Construction: For joining structural steel components .Repair Work: Useful in maintenance and repair tasks across different industries.ConclusionCO2 welding is a valuable technique in modern welding practices, offering a balance of efficiency, cost-effectiveness, and versatility

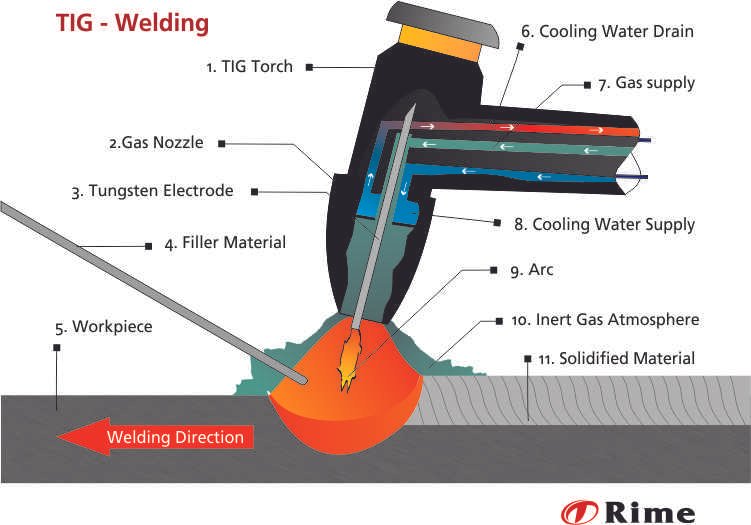

(2)Tig welding

Understanding TIG Welding Machines: A Comprehensive GuideTIG welding, or Tungsten Inert Gas welding, is a versatile and precise welding process used across various industries. This blog explores the features, benefits, and applications of TIG welding machines, making it easier for you to understand their importance.

What is TIG Welding?

TIG welding involves using a non-consumable tungsten electrode to produce the weld. An inert gas, usually argon, protects the weld pool from contamination. This process allows for clean, strong welds on a variety of materials, including stainless steel, aluminum, and magnesium.Key Features of TIG Welding Machines

1. Adjustable Amperage Control Most TIG machines allow you to adjust the amperage, giving you control over the heat input and weld penetration.

2. High Frequency Start This feature enables a smooth arc initiation without contact, ideal for thin materials.

3. AC/DC Capability Many TIG machines can operate on both AC and DC, making them versatile for different metals.

4. Foot Pedal Control This allows for precise control of the heat during welding, enhancing user comfort and accuracy.

5. Cooling Systems Integrated or external cooling systems prevent overheating during extended use.

Advantages of TIG Welding Quality of Welds TIG welding produces clean, high-quality welds with minimal spatter, making it ideal for critical applications. Versatility Suitable for a range of materials and thicknesses, TIG welding can be used in various industries, from automotive to aerospace.Control Welders have greater control over the welding process, which is essential for intricate designs and thin materials

Applications of TIG Welding

1.Aerospace Industry Used for constructing aircraft components that require high-strength and lightweight materials.

2. Automotive Repair Ideal for repairing aluminum parts and high-end vehicles, where precision is crucial.

3. Fabrication Shops Commonly used in metal fabrication for producing detailed structures and components.

4. Artistic Welding Artists often use TIG for creating sculptures and metal art due to its precision and control

Choosing the Right TIG Welding Machine When selecting a TIG welding machine, consider the following factors:- Power Requirements Ensure the machine’s amperage range suits the materials you plan to weld. Portability If you need to move the machine frequently, look for a lightweight model with a sturdy design.

Budget Determine your budget while considering the features that are most important for your welding projects.Brand and Support Opt for reputable brands that offer good customer support and warranties.

TIG welding machines are essential tools for professionals and hobbyists alike, offering precision and versatility. By understanding the features and benefits of these machines, you can make informed decisions that enhance your welding projects.

(3)Milling machine

What is a Milling Machine?

A milling machine is a machine tool that uses rotary cutters to remove material from a workpiece. It can create complex shapes, contours, and features, making it indispensable in producing parts for various applications.

Types of Milling Machines

1. Vertical Milling Machine – The spindle is oriented vertically. – Ideal for producing flat surfaces, slots, and intricate shapes.

2. Horizontal Milling Machine – The spindle is horizontal. – Suitable for cutting deeper grooves and performing heavy-duty work.

3. Universal Milling Machine – Offers both vertical and horizontal milling capabilities. – Provides greater flexibility for various tasks.

4. CNC Milling Machine – Computer Numerical Control machines allow for automation. – Provides high precision and the ability to produce complex shapes with minimal human intervention.

Key Components of a Milling Machine- Spindle Holds and rotates the cutting tool.- Table Supports the workpiece and can move in various directions.- Column Houses the spindle and provides stability.- Power Feed Automatically moves the table for consistent cutting.Cutting Tools Various shapes and sizes to achieve different cuts.

Manufacturing: Creating parts for machinery, vehicles, and consumer products.- Aerospace Producing components that require high precision and strength.- Automotive Machining engine components, frames, and other parts.Medical Devices Fabricating surgical instruments and implants.

Open document Settings open publish panel.

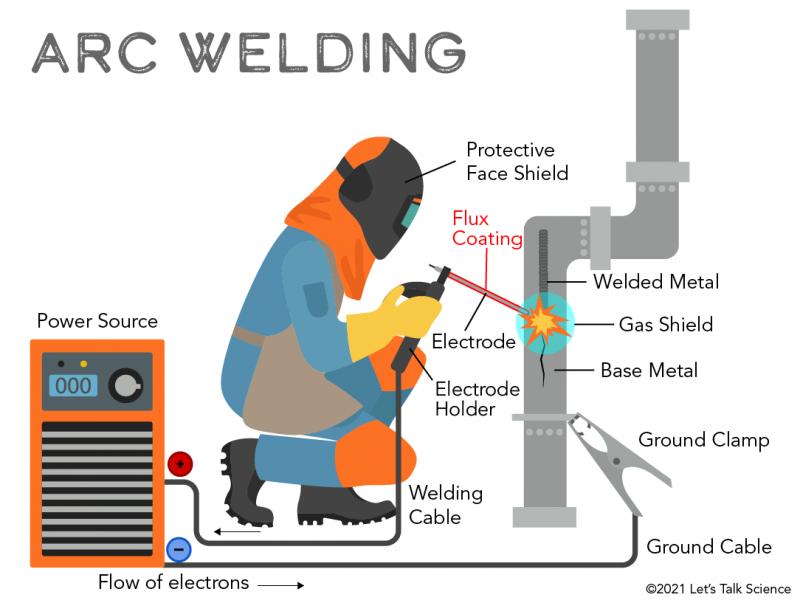

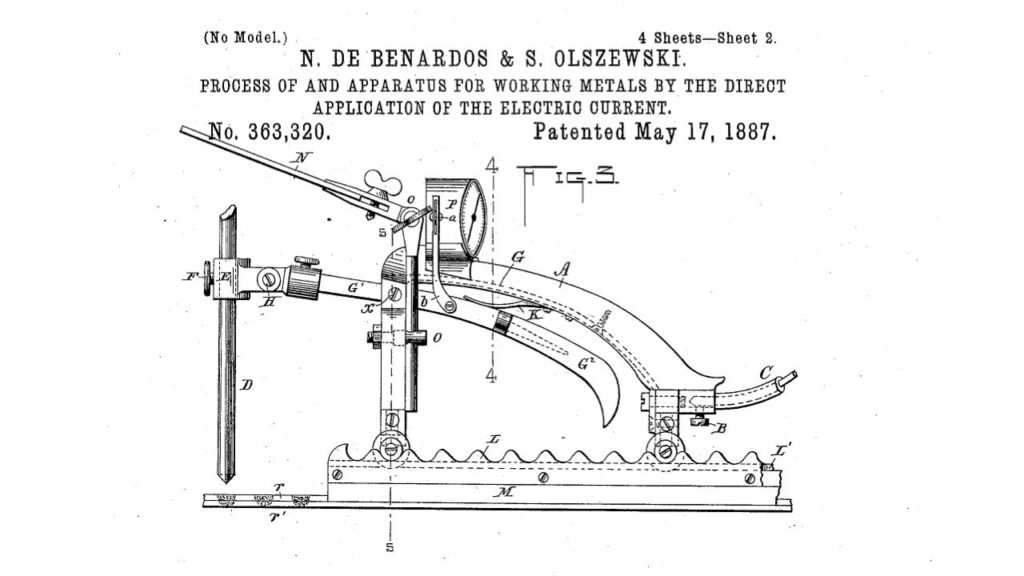

(4)ARC Welding

All country are using the welding . Ikolai Benardos (Russian) and Stanisław Olszewski (Polish) created the first electric arc welding method known as carbon arc welding using carbon electrodes.

welding is use for fabrication method and during the Iron Age, Egyptians first learned how to weld pieces of iron together. Archaeological evidence of early Egyptian welding dates back to 3000 B.C.

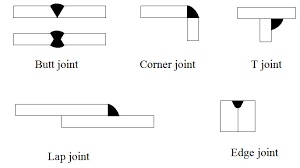

welding joins

1} Butt joint.

2} corner joint.

3} T joint.

4 }lap joint.

5} Edge joints.

(5)Lathe machine

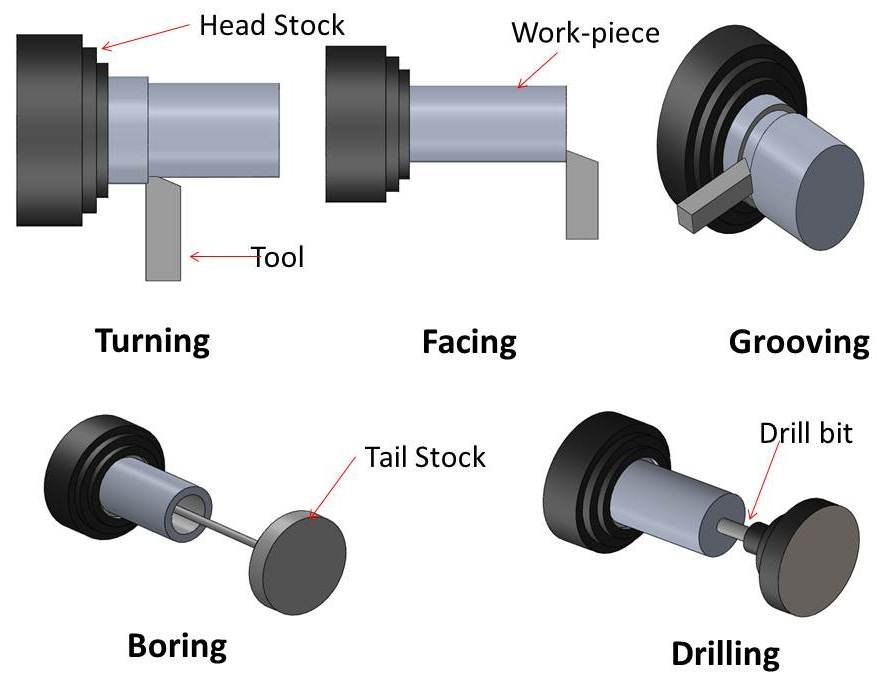

lathe machine is invented by henry Maudsley A lathe consists of four main parts: the bed, spindle, turret, and tailstock. Briefly, the main spindle holds the material and rotates it. The turret, where the tool is attached, moves to shape the part to be machined. The tailstock supports the long workpiece.

This is the part of the lathe machine name head stock , work piece , tail stock ,drill bit Turning is a Substractive machining process that uses a cutting tool, typically a lathe, to achieve a variety of shapes for end-use plastic, metal, wood, or stone parts. Briefly, the use of a rotating metal rod performs turning.

(6)Ferro cement

A Durable Building Material Ferrocement is an innovative construction material that combines the strength of steel reinforcement with the versatility of cement. It has gained popularity in various applications due to its unique properties and benefits. This blog explores what ferrocement is, its advantages, applications, and considerations for use.

What is Ferrocement?

Ferrocement consists of a thin layer of cement mortar reinforced with a network of steel wire mesh or rods. This combination allows ferrocement to maintain high strength while being lightweight and flexible. The material is often used in various construction projects, from small-scale structures to larger applications like boats and tanks. Advantages of Ferrocement

1. Strength and Durability Ferrocement offers excellent tensile and compressive strength, making it suitable for various structural applications. Its resilience against weathering, corrosion, and impact is superior to traditional concrete.2. Lightweight Compared to conventional reinforced concrete, ferrocement is lighter, which can reduce the overall load on foundations and supporting structures.

3. Flexibility in Design Ferrocement can be easily molded into various shapes and sizes, allowing for creative and aesthetic designs. This flexibility is ideal for artistic and functional structures alike.

4. Cost-Effectiveness The materials used in ferrocement are often less expensive than those required for traditional concrete, making it a cost-effective option for many projects.

5.Eco-Friendly Ferrocement construction typically requires less material than conventional methods, leading to reduced waste and a smaller carbon footprint.

Applications of Ferrocement

1. Housing Ferrocement can be used for constructing walls, roofs, and even entire homes, particularly in regions prone to earthquakes or other natural disasters.

2. Water Tanks Due to its impermeability and strength, ferrocement is commonly used for water storage tanks, ensuring safe and reliable storage solutions.

3. Boats and Marine Structures The lightweight nature and corrosion resistance of ferrocement make it an excellent choice for building boats and docks.

4. Sculptures and Artistic Installations Artists and architects often use ferrocement for creating intricate sculptures and design features, thanks to its versatility.

5. Precast Elements Ferrocement can be utilized in precast panels, which can be produced off-site and assembled quickly, speeding up construction timelines.

Considerations When Using Ferrocement-

Expertise Required Working with ferrocement requires specific skills and knowledge, particularly in mixing and applying the mortar and reinforcing it correctly.- Environmental Factors While ferrocement is durable, it is essential to consider local environmental conditions that may affect its longevity, such as exposure to saltwater in marine applications.- Maintenance Regular maintenance may be necessary to ensure the longevity of ferrocement structures, particularly in harsh climates.

(7)Mesurement

Understanding Measurement:

The Foundation of Science and Everyday Life

Introduction measurement is an essential aspect of both our daily lives and scientific endeavors. It provides a way to quantify and compare the world around us, allowing us to make informed decisions, conduct experiments, and communicate findings effectively. In this blog, we will explore the types of measurement, units of measurement, and their significance in various fields.

Types of Measurement

1Length

This measures the distance between two points. Common units include meters, kilometers, feet, and miles. Accurate length measurement is crucial in construction, engineering, and design.

2 Mass

This refers to the amount of matter in an object. It is typically measured in grams and kilograms. Understanding mass is vital in fields like chemistry and nutrition.

3. Volume

Volume measures the space an object occupies. It can be quantified in liters, milliliters, cubic meters, etc. This is particularly important in cooking, manufacturing, and environmental science.

4. Temperature

Measured in degrees Celsius, Fahrenheit, or Kelvin, temperature is critical in various applications, from weather forecasting to industrial processes

.5. Time

Time measurement, typically in seconds, minutes, and hours, is fundamental to scheduling, navigation, and scientific experiments.

Units of Measurement

Measurement relies on standardized units to ensure accuracy and consistency. The International System of Units (SI) is the most widely used system globally, comprising seven base units:- Meter (m) for length- Kilogram (kg) for mass- Second (s) for time- Ampere (A) for electric current- Kelvin (K) for temperature- Mole (mol) for the amount of substance- Candela (cd) for luminous intensity These units can be converted into other units (like converting kilometers to miles) to suit various applications.

Importance of Measurement

1. Scientific Researce

Measurement is crucial in experiments, enabling scientists to collect data, analyze results, and draw conclusions. Accurate measurements lead to reliable results.

2.Engineering and Construction

Precision is key in building structures and designing products. Engineers rely on measurements to ensure safety and functionality.

3. Healthcare

In medicine, measurements such as blood pressure, heart rate, and dosage are vital for diagnosis and treatment.

4. Daily Life

From cooking to budgeting, measurement plays a role in our everyday tasks. Recipes require specific ingredient quantities, and managing finances involves measuring expenses and income

Conclusion

Measurement is a fundamental skill that permeates every aspect of our lives, from scientific exploration to daily activities. By understanding different types of measurement and their significance, we can appreciate the role they play in enhancing our knowledge and improving our decision-making processes. As we continue to advance technologically and scientifically, the importance of accurate and precise measurement will only grow.

Call to Action Consider how measurement impacts your daily life. Whether in cooking, planning a project, or conducting experiments, reflect on the measurements you take and their significance. Share your thoughts in the comments below!

(8)Information Tools for Machines:

Exploring Information Tools for Machines: Enhancing Efficiency and Precision IntroductionIn today’s technology-driven world, machines are integral to various industries, from manufacturing to healthcare. Information tools designed for machines play a crucial role in optimizing performance, enhancing precision, and improving overall efficiency. This blog delves into the various information tools used in machines, their applications, and their significance in modern operations.

Types of Information Tools for Machines

1. Computer-Aided Design (CAD) Software CAD software allows engineers and designers to create detailed 2D and 3D models of machine components. This tool enhances visualization, facilitates modifications, and ensures accuracy in dimensions, which is essential for manufacturing processes.

2. Computer Numerical Control (CNC) Systems CNC systems automate machine tools through computer programming. They allow for precise control over machining processes, leading to consistent quality and reduced human error. CNC is widely used in industries such as aerospace, automotive, and electronics.

3. Machine Learning and Artificial Intelligence AI and machine learning algorithms analyze data from machine operations to optimize performance. These tools can predict maintenance needs, detect anomalies, and enhance decision-making, leading to increased productivity and reduced downtime.

4. Enterprise Resource Planning (ERP) Software ERP systems integrate various business processes, including manufacturing, supply chain, and inventory management. By providing real-time data, ERP tools help organizations streamline operations and improve resource allocation.

5. Data Acquisition Systems (DAS) DAS collect and analyze data from machines in real time. These systems monitor performance metrics, enabling operators to make informed decisions quickly. Applications include quality control, predictive maintenance, and process optimization.6.

Human-Machine Interface (HMI)

HMIs provide a user-friendly interface for operators to interact with machines. They display real-time data, control machine operations, and enable troubleshooting. An effective HMI enhances user experience and improves operational safety.

Applications Across Industries

1. Manufacturing Information tools like CAD and CNC systems are vital for producing complex components with high precision. They enable rapid prototyping and mass production while minimizing waste.

2. Healthcare In medical devices, information tools ensure accuracy in diagnostics and treatment. Advanced imaging software and robotic surgery systems rely on precise data to enhance patient outcomes.

3. Transportation In the automotive and aerospace industries, simulation software and predictive maintenance tools improve safety and efficiency. They help in designing vehicles and monitoring performance in real-time.

4. Construction Information tools in construction include project management software and BIM (Building Information Modeling). These tools enhance collaboration, streamline workflows, and improve project delivery times.

Benefits of Information Tools

– Increased Efficiency Automation and data analysis minimize manual tasks, leading to faster production times and reduced costs.- Enhanced Accuracy Precision tools reduce errors in manufacturing and operations, ensuring high-quality outcomes.

Conclusion Information tools for machines are revolutionizing industries by enhancing efficiency, accuracy, and productivity. As technology continues to evolve, the integration of advanced tools will become increasingly critical in maintaining a competitive edge. Embracing these tools not only benefits individual organizations but also contributes to the overall advancement of industry standards.

Call to Action Consider the information tools your organization utilizes. Are there areas for improvement? Explore new technologies that could enhance your machine operations and share your insights in the comments below!

(9)Carpentry

Carpentry

| UncategorizedThe Art of Carpentry:Crafting with WoodIntroduction Carpentry is more than just a trade it’s an art form that combines skill, creativity, and a deep appreciation for nature’s material wood.

From building sturdy furniture to constructing beautiful homes, carpentry has been a vital craft throughout history. In this blog, we’ll explore the essentials of carpentry, techniques, tools, and tips for both beginners and seasoned woodworkers.

Understanding Carpentry Carpentry involves shaping and assembling wooden structures and products. It can be broadly categorized into two main types:

1.Rough Carpentry This involves framing, roofing, and structural work, focusing on the building’s skeleton and foundational elements.

2.Finish Carpentry This includes detailed work such as cabinetry, molding, and trim, which enhance the aesthetic appeal of a space.Essential Tools for Carpenters Every carpenter needs a reliable set of tools. Here are some must-haves:-

Measuring Tools Tape measures, squares, and calipers ensure precision in your projects.Cutting Tools Saws (hand saws, circular saws, and jigsaws) are essential for cutting wood to size.-Joining Tools Hammers, chisels, and drills help in joining pieces together effectively.Finishing Tools Sandpaper and finishing brushes or sprayers give your projects a professional touch.

Basic Techniques to Master

1.Measuring and Marking Always measure twice and mark clearly to avoid mistakes.

2.Cutting Learn various cutting techniques, including cross-cutting and ripping, to handle different types of cuts.

3.Joining Familiarize yourself with various joining methods, such as butt joints, miter joints, and dovetails.

4.Finishing Mastering the art of finishing can elevate your work from good to great. Experiment with stains, paints, and sealants.

Tips for Beginners

Start Small Begin with simple projects like a birdhouse or a small shelf to build your skills and confidence.

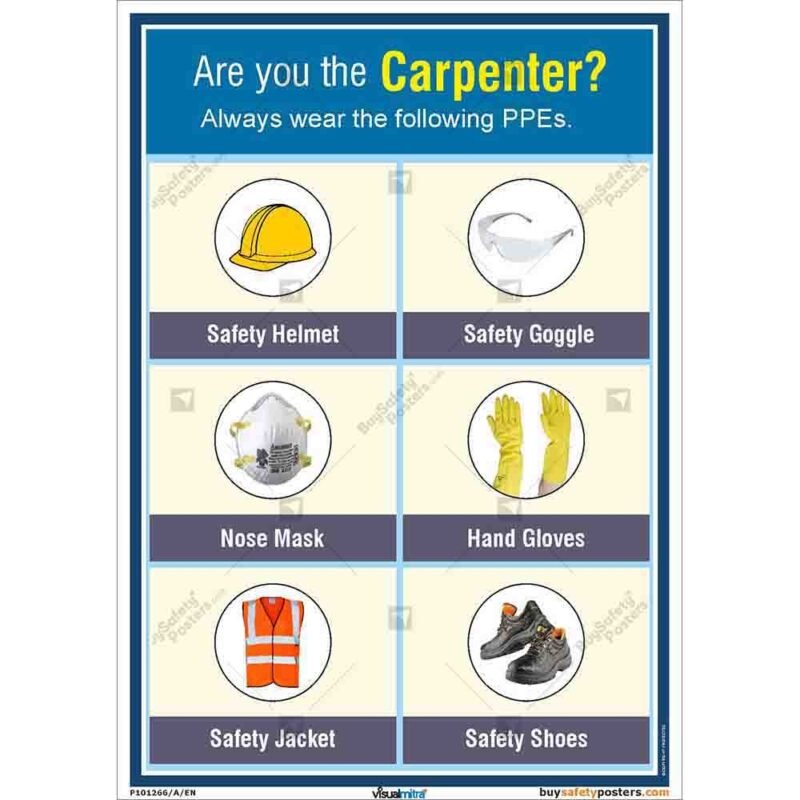

Safety First Always wear protective gear, such as goggles and gloves, to keep yourself safe while working.-

Learn from Others Join local woodworking clubs or online communities to exchange tips and ideas with fellow carpenters.

Project IdeasHere are a few project ideas for aspiring carpenters:

1.Bookshelf A classic project that helps you practice measuring and cutting.

2.Coffee Table A slightly more advanced project that allows for creative design.

3.Garden Planter Perfect for outdoor enthusiasts and great for practicing joinery.

Conclusion

Carpentry is a rewarding pursuit that not only allows you to create functional items but also gives you a chance to express your creativity. Whether you’re looking to build furniture or simply enjoy the process of working with your hands, carpentry offers endless opportunities for growth and satisfaction. So gather your tools, find your inspiration, and start crafting.

Resources for Further Learning.

Books Look for woodworking books that cover techniques and project ideas.-

Online Courses Websites like Skillshare and Udemy offer carpentry courses for all skill levels.-

YouTube Follow carpentry channels for visual demonstrations and tutorials.Embrace the art of carpentry and let your creativity take shape.

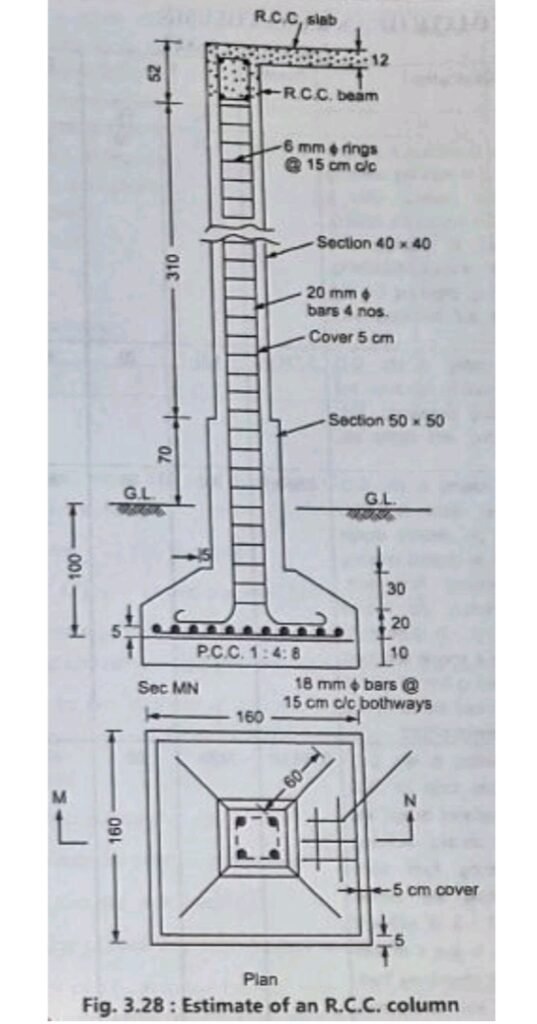

(10)RCC Columns

Understanding RCC Columns:

Essential Elements of Structural Design

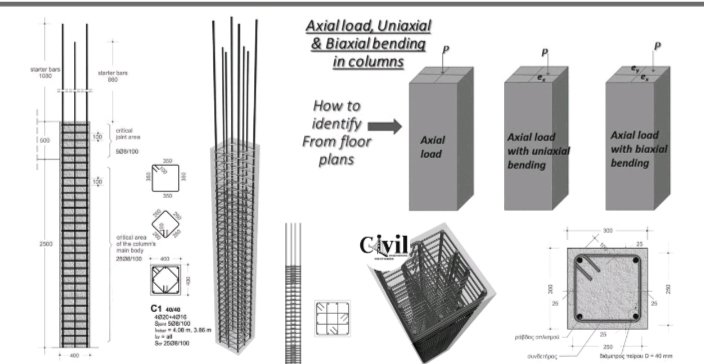

IntroductionReinforced Cement Concrete (RCC) columns are fundamental components in modern construction, providing strength and stability to buildings and structures. This blog will delve into the significance of RCC columns, their design principles, construction techniques, and common applications.

What is an RCC Column?

An RCC column is a vertical structural element made from concrete reinforced with steel bars (rebars). The combination of concrete’s compressive strength and steel’s tensile strength makes RCC columns capable of bearing heavy loads while resisting various stresses.

Importance of RCC Columns

1.Load-Bearing Capacity

RCC columns support the weight of beams, slabs, and other structural components, distributing loads effectively.

2. Stability

They provide stability to the overall structure, ensuring it can withstand environmental factors like wind and earthquakes.

3. Durability

RCC columns are resistant to fire, corrosion, and weather, enhancing the lifespan of a building.

Design Principles

1. Load Calculation

Before designing an RCC column, engineers must calculate the expected loads, including dead loads (weight of the structure) and live loads (occupants, furniture, etc.). This ensures that the column can support the anticipated weight safely.

2. Dimensions and Proportions

The size and shape of the column depend on the load it carries and the overall architectural design. Common shapes include rectangular, square, and circular columns.

3. Reinforcement

The amount and placement of steel reinforcement are crucial for the column’s performance. Typically, longitudinal bars are placed vertically, while ties (transverse reinforcement) are added to resist lateral forces and prevent buckling.

4. Concrete Grade

Selecting the appropriate concrete grade is essential for achieving the desired strength. Higher grades of concrete (e.g., M25, M30) are often used for columns to ensure durability and load-bearing capacity.

Construction Techniques

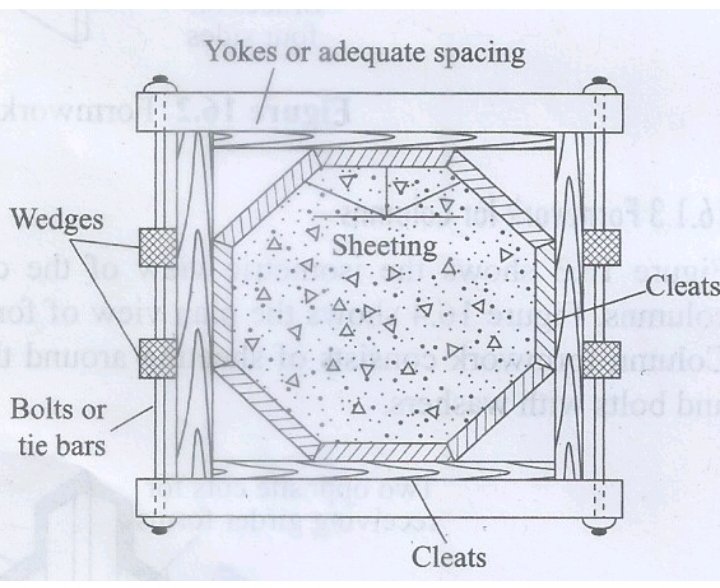

1. Formwork

Formwork is used to shape the concrete. It must be sturdy and properly aligned to ensure the column maintains its intended dimensions.

2.Rebar Placement

Rebars should be accurately placed according to the design specifications. Proper overlap and binding are essential for effective load transfer.

RCC columns are integral to multi-story residential structures, providing necessary support. –

Commercial Buildings

: In offices and shopping centers, RCC columns enable open floor plans and larger spaces.-

Bridges

RCC columns are used in bridge construction to support spans and enhance structural integrity.

Industrial Structures

Factories and warehouses often utilize RCC columns for heavy load-bearing applications.

Conclusion

RCC columns are vital components in the field of construction, combining strength, stability, and durability. Understanding their design and construction principles is essential for anyone involved in building design or architecture. By employing proper techniques and adhering to safety standards, engineers and builders can create structures that withstand the test of time.

Further Resources-

Books

Look for textbooks on structural engineering for in-depth knowledge.

Online Courses

Platforms like Coursera and edX offer courses in structural design.-

Industry Guidelines

Refer to codes and standards from organizations like the American Concrete Institute (ACI) for best practices.By mastering the art and science of RCC columns, we can ensure safer and more resilient structures for the future.

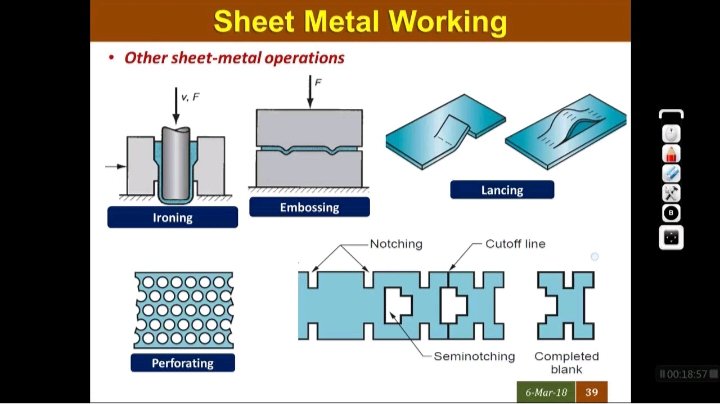

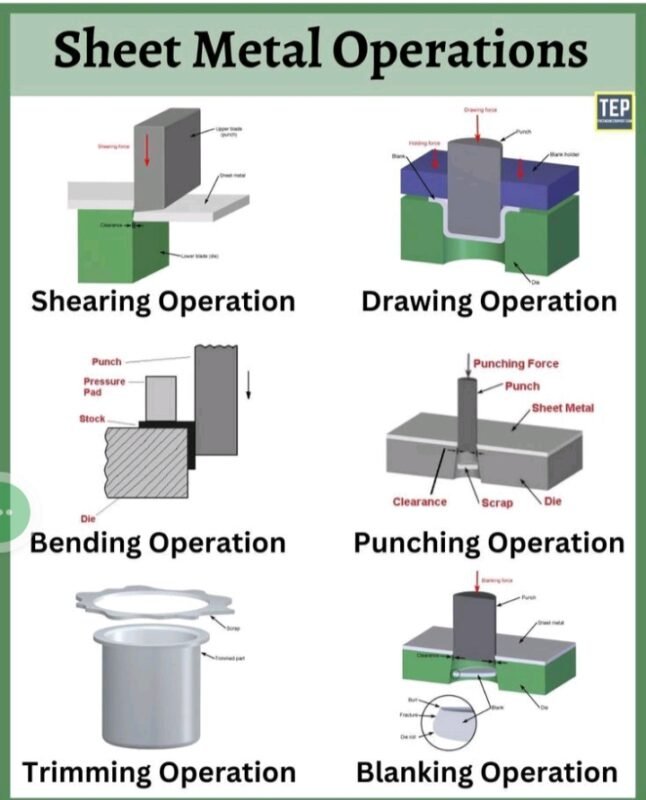

(11)Metal Sheet Work

The Art and Craft of Metal Sheet Work metal sheet work is a fascinating blend of artistry and engineering, allowing creators to transform raw materials into functional and decorative pieces. Whether you’re a hobbyist or a professional craftsman, understanding the basics of metal sheet work can elevate your projects and enhance your skills.

What is Metal Sheet Work?

Metal sheet work involves manipulating thin sheets of metal to create various objects, from intricate sculptures to practical items like furniture and tools. Common metals used include aluminum, steel, copper, and brass, each offering unique properties for different applications.## Tools and Materials before diving into metal sheet work, familiarize yourself with essential tools and materials:

Tools

1. Shears For cutting metal sheets into desired shapes.

2. Bending Brake To bend sheets accurately at specific angles.

3. Welding Equipment For joining pieces together.

4. Drills For creating holes for screws or rivets.

6. Safety Gear Including gloves, goggles, and ear protection.

Materials-

Metal Sheets Choose the thickness and type based on your project.-

Fasteners Such as screws, rivets, or welding rods.-

Finishing Products Paint, polish, or sealants for aesthetics and protection.

Techniques in Metal Sheet Work Cutting precision is key. Use shears or plasma cutters for clean cuts, ensuring safety by wearing protective gear.

Bending employ a bending brake for accurate bends. Measure carefully and make incremental adjustments to avoid over-bending.

Joining welding provides a strong bond but requires practice. Alternatively, use rivets or screws for ease of assembly, especially for beginners.

Finishing after assembling your piece, consider sanding and polishing for a refined look. Finishing techniques can also include painting or patination to achieve desired aesthetics.

Projects to Try

1.Metal Wall Art Create decorative pieces that reflect your style.

2.Furniture Design items like tables or shelving units using metal sheets for a modern touch.

3.Garden Decor Craft sculptures or planters that withstand outdoor elements.

4. Functional Items Build items such as trays or storage solutions that combine utility and artistry.

Tips for Success-

Practice Start with simple projects to build confidence and skills.- Plan Sketch your design and measurements before cutting.- Safety First Always prioritize safety when working with tools and materials.-

Experiment Don’t be afraid to try new techniques or designs; creativity is key in metal work.

Conclusion

metal sheet work offers endless possibilities for creativity and craftsmanship. Whether you’re crafting functional items or artistic pieces, mastering the techniques involved can lead to rewarding and impressive results. Embrace the journey of metalworking, and let your imagination guide you to create unique, lasting works of art.

(12)FRP practical

Understanding FRP:A Comprehensive Guide

What is FRP?

Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. It combines the lightweight and corrosion-resistant properties of polymers with the strength and rigidity of fibers, making it a versatile material in various applications.

Benefits of FRP

1. Lightweight FRP is significantly lighter than traditional materials like steel or concrete, which simplifies transportation and installation.

2.Corrosion Resistance The polymer matrix provides excellent resistance to chemicals and environmental conditions, making FRP ideal for use in harsh environments.

3. High Strength-to-Weight Ratio FRP offers superior strength relative to its weight, enabling the construction of strong yet lightweight structures.

4.Design Flexibility FRP can be molded into complex shapes, allowing for innovative design solutions in construction and manufacturing.

5.Low Maintenance Due to its durability and resistance to environmental damage, FRP typically requires less maintenance than conventional materials.

Applications of FRP

1. Construction FRP is used in bridge construction, reinforcement of concrete structures, and architectural applications. Its lightweight nature reduces the load on foundations.

2. Aerospace and Automotive In these industries, FRP is used to manufacture components that require high strength but low weight, improving fuel efficiency and performance.

3. Marine FRP is ideal for boat hulls and other marine applications due to its resistance to saltwater and minimal maintenance needs.

4.Electrical and Electronics FRP insulators are widely used in the electrical industry, as they are non-conductive and resistant to environmental factors.

Challenges and Considerations

1.Cost While FRP offers many benefits, its initial cost can be higher than traditional materials, which may deter some projects.

2.Manufacturing Complexity The production of FRP components can be complex and requires specialized knowledge and equipment.

3. Recyclability Recycling FRP materials is challenging, leading to environmental concerns regarding waste management.

FRP is a revolutionary material with numerous advantages that make it a suitable choice for various industries. Understanding its benefits, applications, and challenges is crucial for leveraging its potential effectively. As technology progresses, FRP will likely play an increasingly vital role in the future of materials engineering. For more insights on innovative materials and their applications, stay tuned to our blog!

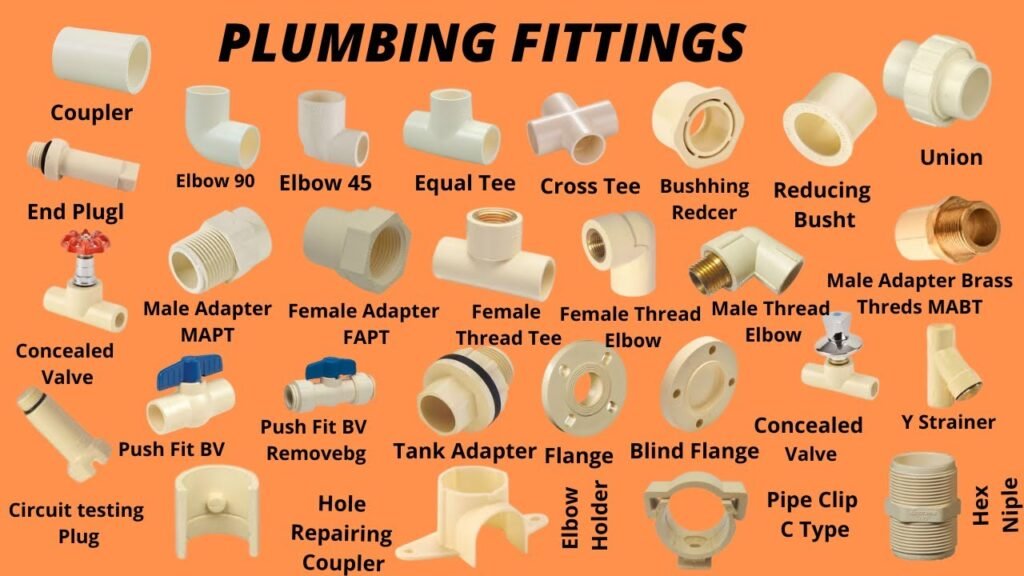

(13)Plumbing work

The Essential Guide to Plumbing: Tips, Tricks, and Maintenance welcome to our plumbing blog, where we aim to provide homeowners and DIY enthusiasts with valuable insights into the world of plumbing. From common issues to preventative maintenance, we’ll cover everything you need to know to keep your plumbing system in top shape Understanding Your Plumbing System The Basics your plumbing system is divided into two main parts: the supply system, which brings fresh water into your home, and the drainage system, which removes wastewater. Understanding how these systems work can help you identify problems before they escalate.

Common Plumbing Issues

1. Leaky Faucets A constant drip can waste gallons of water and increase your bill.

2.Clogged Drains Hair, grease, and soap buildup can lead to slow drainage or complete blockages.

3. Running Toilets This can waste water and lead to higher utility bills.

4. Low Water Pressure Often caused by leaks or blockages in the pipes.

DIY Plumbing Tips

Fixing a Leaky Faucet

1.Turn Off the Water Supply Locate the shut-off valve under the sink.

2.Disassemble the Faucet Carefully remove the handle and unscrew the packing nut.

3.Replace the Washer Check for wear and tear and replace it if necessary.

4.Reassemble and Test Put everything back together and turn the water supply on.

Clearing Clogged Drains

1.Boiling Water Pour boiling water down the drain to dissolve grease.

2. Baking Soda and Vinegar Pour half a cup of baking soda followed by half a cup of vinegar, then flush with hot water.

3.Plunger If the clog persists, use a plunger for more forceful action.

Fixing a Running Toilet

1.Remove the Tank Lid Check the flapper valve for any signs of wear.

2.Adjust the Chain Ensure the chain isn’t too tight or too loose.

3. Replace Parts If necessary, replace the flapper or other components.

Preventative Maintenance

Regular Checks-

Inspect visible pipes for leaks or corrosion.- Check for signs of water damage around fixtures.- Test your water pressure regularly to ensure it’s within a normal range.

Seasonal Maintenance-

In colder months, insulate pipes to prevent freezing.- Clean gutters and downspouts to ensure proper drainage away from your home.

Professional Inspections Consider hiring a licensed plumber for annual inspections to catch potential issues early. They can provide advice tailored to your specific plumbing system.

Sustainable Plumbing Practices Water-Saving Fixtures Invest in low-flow faucets and showerheads to reduce water usage without sacrificing performance.Rainwater Harvesting Consider installing a rain barrel to collect rainwater for irrigation, helping conserve municipal water supplies.

Conclusion

A little knowledge goes a long way when it comes to plumbing. By understanding your plumbing system and performing regular maintenance, you can save money, prevent major issues, and ensure your home stays comfortable. Whether you’re tackling small repairs yourself or calling in a professional, being proactive is key to a healthy plumbing system. Stay tuned for more tips and tricks in future posts!

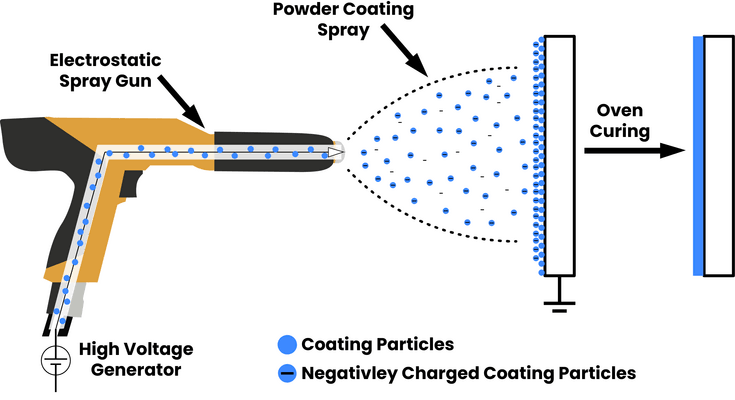

(14)Powder coating

What is Powder Coating?

Powder coating is a modern finishing process that applies a dry powder to metal surfaces, providing a durable, high-quality finish. Unlike traditional liquid paint, powder coating is free of solvents and is applied electrostatically, resulting in a uniform and resilient layer.

Benefits of Powder Coating

1. Durability Powder-coated surfaces are resistant to scratches, chips, and fading, making them ideal for both indoor and outdoor applications.

2. Environmentally Friendly Since it doesn’t contain solvents, powder coating emits fewer volatile organic compounds (VOCs), making it a more eco-friendly option.

3. Variety of Finishes Powder coating is available in a wide range of colors, textures, and finishes, including matte, gloss, and metallic.

4. Cost-Effective Though the initial setup can be higher than liquid paint, powder coating typically leads to lower maintenance costs and a longer-lasting finish.

5.Uniform Coverage.The electrostatic application process ensures even coating, reducing the chances of runs or drips.

The Powder Coating Process

1. Surface Preparation The first step involves cleaning the metal surface to remove dirt, grease, or rust. This is crucial for ensuring proper adhesion.

2. Application The powder is applied using an electrostatic spray gun, which charges the powder particles, causing them to adhere to the grounded metal surface.

3. Curing The coated object is then placed in an oven, where heat causes the powder to melt and chemically react, forming a hard, protective layer.4.Cooling After curing, the item is allowed to cool, solidifying the finish and ensuring durability.

Applications of Powder Coating

Automotive Parts Powder coating is popular in the automotive industry for wheels, bumpers, and frames due to its resilience and aesthetic appeal.

Furniture Many outdoor and indoor furniture pieces are powder-coated for enhanced durability and color retention.

Industrial Equipment Equipment exposed to harsh environments benefits greatly from the protective qualities of powder coating.

Bicycles and Sports Equipment

The lightweight and tough finish is perfect for bikes and sporting goods, providing both protection and style.

Conclusion

powder coating is an innovative finishing technique that offers numerous advantages over traditional painting methods. Its durability, environmental benefits, and aesthetic versatility make it an excellent choice for a wide range of applications. Whether you’re considering powder coating for personal projects or industrial uses, understanding the process and its benefits can help you make an informed decision. If you’re looking for a reliable powder coating service, ensure to choose a provider with a proven track record and high-quality materials to achieve the best results for your projects.

(15)Plasma machine

Exploring the Plasma Machine: A Game Changer in Modern Technology

Introduction

In recent years, plasma machines have emerged as pivotal tools across various industries, revolutionizing manufacturing processes and enhancing precision in tasks ranging from cutting to welding. This blog will delve into the functionality, applications, and benefits of plasma machines, as well as their impact on future technological advancements.

What is a Plasma Machine?

A plasma machine utilizes ionized gas (plasma) to perform cutting, marking, or welding on various materials. The process involves generating a high-temperature plasma arc that melts and expels material, allowing for clean and precise cuts.

How Does It Work?

- Ionization: The machine generates a high-voltage electric arc that ionizes the gas, turning it into plasma.

- Cutting Process: The plasma is directed through a nozzle, where it focuses energy on the workpiece, melting it instantly.

- Material Removal: As the plasma cuts through, the molten material is blown away by the force of the plasma jet.

Applications of Plasma Machines

- Metal Fabrication: Used extensively in industries like automotive, aerospace, and construction for cutting and shaping metal parts.

- Art and Design: Artists use plasma cutting for intricate designs in metalwork, creating unique sculptures and decorative items.

- Manufacturing: Ideal for creating components with high precision, plasma machines enhance efficiency in production lines.

- Repairs and Maintenance: Useful in repair shops for cutting and fitting parts with precision.

Advantages of Plasma Machines

- Precision and Accuracy: Plasma cutting provides clean edges and minimizes the need for further finishing.

- Versatility: Capable of cutting through various materials, including steel, aluminum, and even some plastics.

- Speed: Faster than traditional cutting methods, plasma machines significantly reduce production times.

- Cost-Effective: The efficiency and speed of plasma machines can lower operational costs in the long run.

Future of Plasma Technology

As industries continue to innovate, the future of plasma machines looks promising. Advancements in automation and AI integration are likely to enhance their functionality, leading to smarter and more efficient machines. Additionally, developments in plasma technology could lead to new applications in fields like medicine and environmental science.

(16)Brick Construction

The Art and Science of Brick Construction Introduction Brick construction has stood the test of time, serving as a foundational method in architecture for thousands of years. Its durability, aesthetic appeal, and versatility make it a popular choice for builders and architects alike. In this blog, we’ll explore the history, benefits, techniques, and future of brick construction.

A Brief History of Brick

The use of bricks dates back to ancient civilizations, with evidence found in places like Mesopotamia and the Indus Valley. These early bricks were made from mud and sun-dried, paving the way for the fired clay bricks we recognize today. The Romans perfected brick-making techniques, leading to iconic structures like the Colosseum that still stand strong.Why Choose Brick?

1. Durability Bricks are known for their strength and longevity. They resist weathering, pests, and fire, making them an ideal choice for both residential and commercial buildings.

2. Aesthetic Appeal with a variety of colors, textures, and sizes, bricks offer endless design possibilities. From traditional to contemporary styles, they can enhance the visual appeal of any structure.

3. Energy Efficiency Brick walls provide excellent thermal mass, helping to regulate indoor temperatures. This can lead to reduced energy costs and a smaller carbon footprint over time.

4. Low Maintenance once properly installed, brick structures require minimal maintenance. Occasional cleaning and sealing are usually sufficient to keep them in good condition.

Techniques in Brick Construction

1. Traditional Bricklaying

The most common method involves laying bricks in a pattern using mortar. This requires skill and precision to ensure structural integrity and aesthetic appeal. Common patterns include running bond, stack bond, and herringbone.

2. Reinforced Brickwork

In areas prone to earthquakes or high winds, reinforced brickwork incorporates steel rods or mesh to enhance structural stability. This technique ensures that buildings can withstand external forces.

3. Thin Brick Veneer

For those seeking the aesthetic of brick without the weight, thin brick veneer is a popular choice. It can be applied to a variety of surfaces, providing the look of traditional brick with less structural demand.

Challenges in Brick

Construction Despite its many advantages, brick construction does come with challenges. The initial cost can be higher compared to other materials. Additionally, bricklaying requires skilled labor, which can affect project timelines. Proper drainage and moisture control are also essential to prevent issues like efflorescence and mold.

The Future of Brick Construction

As sustainable building practices gain traction, innovations in brick-making are emerging. Recycled materials and eco-friendly manufacturing processes are being developed, making brick construction even more sustainable. Additionally, advances in design software allow architects to create complex and innovative brick structures.