/////////////////////// WORK IN PROGRESS/////////////////////////////

AIM : to make a 3d printer for a very affordable prices

NEED OF THE PROJECT : 3d printers are a hell costly the crappyest ones starting around 30 $

And medium ones around 1 lac and the best around 3-8 lacs .

The one that we use at vigyan ashrma is the Julia advance from the Julia series from the fractle company . itn costs around 8 ;lacs which is inaffordable the common man for prototyping

Name of my printer: MIKASA

FEATURES OOF THIS PROJECT :

- This is a cheap alternative costing around 3000-5000rs

- this is a multi task9ng machine .i.e this is a 3d printer , laser cutter , vinyl cutter , detachable machine , miller machine , PCB miller .

HOW DOES A 3D PRINTER WORKS :

A 3d printer uses the 3 axis too controls its position in the 3 dimensional world

If you need a pointer at the point (20 20 20) this would corresponds to the following axis

Move X axis in the X direction with 20 units

Move Y axis in the Y direction with 20 units

Move Z axis in the Z direction with 20 units

Finaly the extruder eextrudees the plaastics onto the heating plaate and and it sticks there and is left there too cool off

Mikasa 3d printers’ progress :

- As shown above the 3d printer usesd a strtepper motor to control itself

- But to cut ciosts aand imporove the effeincy and printing speed I am going tpo mmake yuse of trhe servop motor

- Again the tytpe odf servo motor that ii am goimng to be requiring is a 360degree servo

- I hopped onto the web and searched onto the information for a 3650 degree servo and fond that they are daam costly take a look atv thius

- /////////////// thue photo of the page omnn which this servo asd sold /////////////

- So again make a servo out frpom the DC gear mot6or

- Now as ashoiwn above we need to know the accurate position of the mpotor toio know about ioits position so we make use of a rotary encoder

MAKING A ROTARY ENCODER :

- Downlkoad the inscape file provided below

- ////////////// inscape file

- Load the inscape fi8le into the laser cutter

- If you don’t have a laser cutter then no need tro worry because I have got yopu covered

- Take the file provided below to a normal printer inb a shop or something and cut this on a A4 size paper you will bee ohbi9viousl;y going to need to 4 of these encoders 3 for the 3 axixs and 1 for the extruder mnotoior

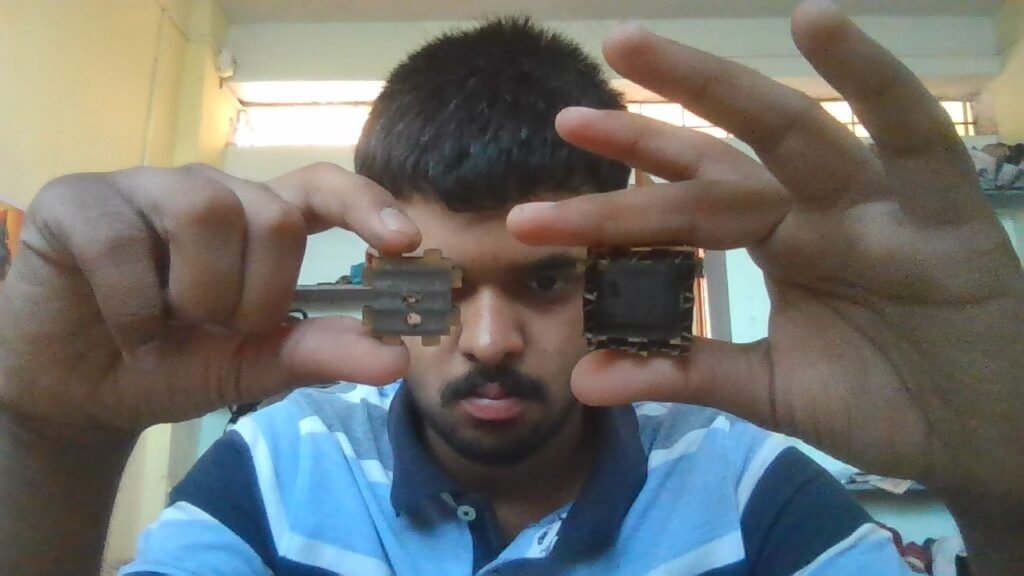

- The [pieses will look sometinmg lilke this