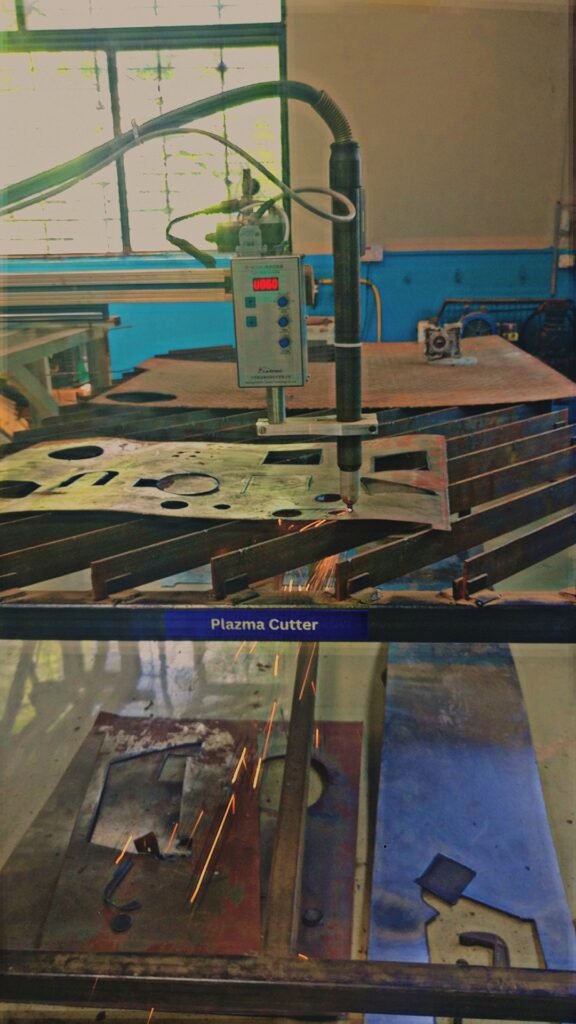

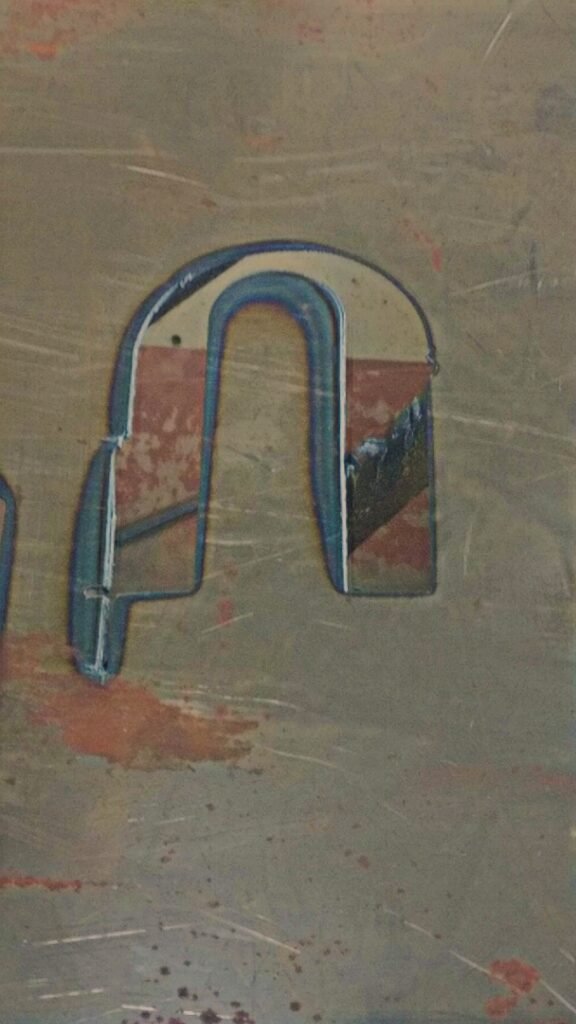

. Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well.

The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. This increases the temperature and velocity of the plasma emanating from the nozzle. The temperature of the plasma is in excess of 20 000°C and the velocity can approach the speed of sound.

How useful is a plasma cutter?Plasma Cutters Can Cut Almost Any Form of MaterialIf you wanted to cut various forms of metal (plate, tube, angle, beam, grating), you would need multiple different types of saws or shears. A plasma cutter can do it all.

Plasma means: When in a liquid or a gas the number of free charge carriers is so large that charge carriers affect the physical properties of the medium substantially. When electromagnetic interactions between the charged particles take place.