Welding

.

Types of welding joints

- Corner joint

- Tee joint

- butt joint

- Lap joint

- edge joint

. WELDING MEANING

Welding Jo do dhaatu ko ek saman jode use welding kahate Hain aur bahut tarah ke welding hoti hai

Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both forming a join as the parts cool. Welding is usually used on metals and thermoplastics but can also be used on wood.

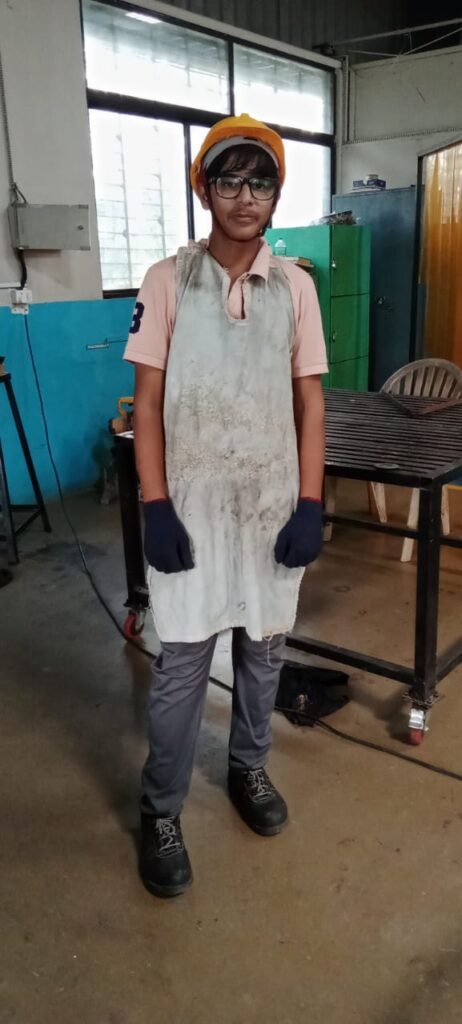

Safety shoes , safety googles ,safety helmet , mask, hand gloves ,ear safety.

MEASUREMENT

.

Measurement is the process of expressing the quantity of a physical property in numbers. It is a comparison process where the quantity of a physical property is compared to a predetermined quantity, which is known as the unit for that property.

. VERNIER CALIFOR

A vernier caliper is usually used to measure the diameter of circular objects. The circular jaws of the vernier caliper fit perfectly on the circumference of round objects. Vernier caliper consists of two scales, the main scale which is fixed, and a moving vernier scale. The main scale has readings in millimeters.

MILLING MACHINE

The milling machine is one of the interesting machines from the past. From gear cutting & slotting to machining flat surfaces, it does everything. Sometimes, these machines are called ‘MTM’ – Multi-Tasking Machines. In this article, we shall discuss the working principle of these machines with parts.

Milling machine operations are machining processes that involve the use of milling cutters to remove material from a workpiece’s surface to achieve specific shapes and dimensions. These operations offer a diverse array of techniques for shaping, cutting, and machining materials with precision .

METAL SHEET INTO DUST PAN

Make a metal sheet which has less weight.Mark the sheet as 29 cm in length and 29 cm in breadth.Cut the sheet as per marking by a small hand cutter.Bend the sheet 1 cm inside at the edges using bending machine to prevent cutting of hands while using.At lengthwise marking leave 5 cm .

A dust pan is a shovel-shaped pan used for sweeping. It is used to pick up the dust and dirt that remain after sweeping. It can be used along with long brush or broom to scoop up dirt.

High quality short handed plastic dustpan and brush sets. Long handled dustpan and brush set – the long handle makes sweeping more comfortable as no bending down is neededLobby upright dustpans. Metal large hooded dustpan.

Machine aur machine ka ISTAMAL

Machine aur machine ka istamal

. 1) FIRST AID BOX

. 2). CO2 WELDING MACHINE

. 3) WELDING TABLE

. 4) ARC WELDING MACHINE

. 5) TIG WELDING MACHINE

. 6) WOOD CUTTER MACHINE

.

7) bench wood cutting machine

TIG WELDING MACHINE

How does a TIG welder work?

TIG stands for tungsten inert gas and is technically called gas tungsten arc welding (GTAW). The process uses a non-consumable tungsten electrode that delivers the current to the welding arc. An inert gas, typically argon, protects and cools the tungsten and weld puddle

What is the basic principle of TIG welding?

Working Principle of TIG WeldingTungsten Inert Gas (TIG) welding operates on the same principle as arc welding, where a strong arc is created between a tungsten electrode and the workpiece. Typically, the workpiece is connected to the positive terminal while the electrode is connected to the negative terminal.

. TIG stands for tungsten inert gas and is technically called gas tungsten arc welding .

MIG WELDING MACHINE

. MIG welding uses a constant voltage power supply to create an electric arc that fuses the base metal with a filler wire that is continuously fed through the welding torch. At the same time, an inert shielding gas is also fed through the gun, to protect the weld pool from atmospheric contamination.

What is MIG welding full detail?

What is Metal Inert Gas (MIG) Welding? Metal Inert Gas (MIG) welding is an arc welding process that uses a continuous solid wire electrode heated and fed into the weld pool from a welding gun. The two base materials are melted together forming a join.

WELDING KARTANA SAFETY

What is the use of MIG?

Like other welding methods, MIG is used to join metal parts together — our customers choose it a lot for their steel, aluminum, and cast iron parts.

. PAINTING

The curing process for powder coating is normally done in a special oven; the coating has to be exposed to a temperature range of 350 to 400 degrees Fahrenheit (160 to 210 degrees Celsius) for 20 minutes.

Painting is a visual art, which is characterized by the practice of applying paint, pigment, color or other medium to a solid surface (called the “matrix” or “support”). The medium is commonly applied to the base with a brush, but other implements, such as knives, sponges, and airbrushes, may be used.

Painting is the act or process of using paint. The paint can create an artwork known as a painting, or it can be used more practically as a protective coating or form of decoration. Paintings are a form of visual art that captures the expression of ideas and emotions on a two-dimensional surface.

OVEN FOR POWDER COATING

This oven is used for curing of powder coating freshly done on the oven. During the curing process (in the oven) a chemical cross-linking reaction is triggered at the curing temperature and it is this chemical reaction which gives the powder coating many of its desirable properties.

The powder coating process involves three basic steps: part preparation or the pre-treatment, the powder application, ands .

Powder coating is based on the principle that objects with opposite electric charges (positive and negative) attract one another. Powder particles are negatively charged by passing them through a special spraying gun. This results in an electric field between the spray gun and the earthed component.

7 Tank Process for Powder Coating on Metal is a seven steps process. These are steps which include Degrease, Rinse, Pickling, Rinse, Phosphating, Rinse, and Passivation.

After the parts are coated with powder, it is crucial to bake them within a proper temperature range. This cure process requires a certain temperature for a certain length of time in order to reach full cure and establish the full film. The powders cure at 300°F to 400°F for 10 – 15 minutes at part temperature.

The curing process for powder coating is normally done in a special oven; the coating has to be exposed to a temperature range of 350 to 400 degrees Fahrenheit (160 to 210 degrees Celsius) for 20 minutes.

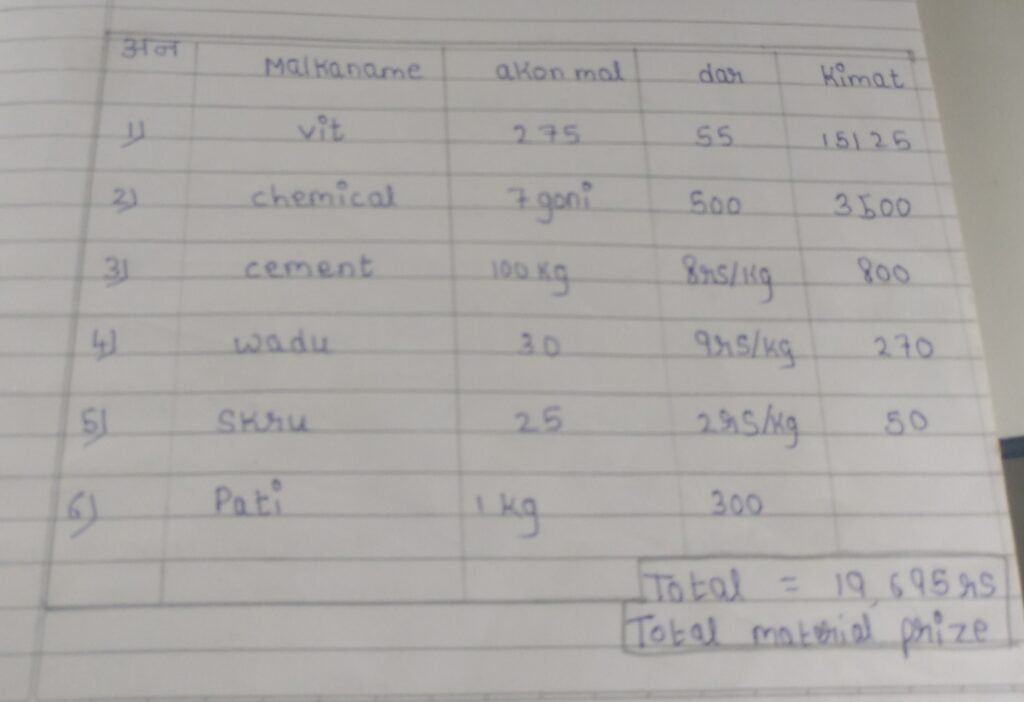

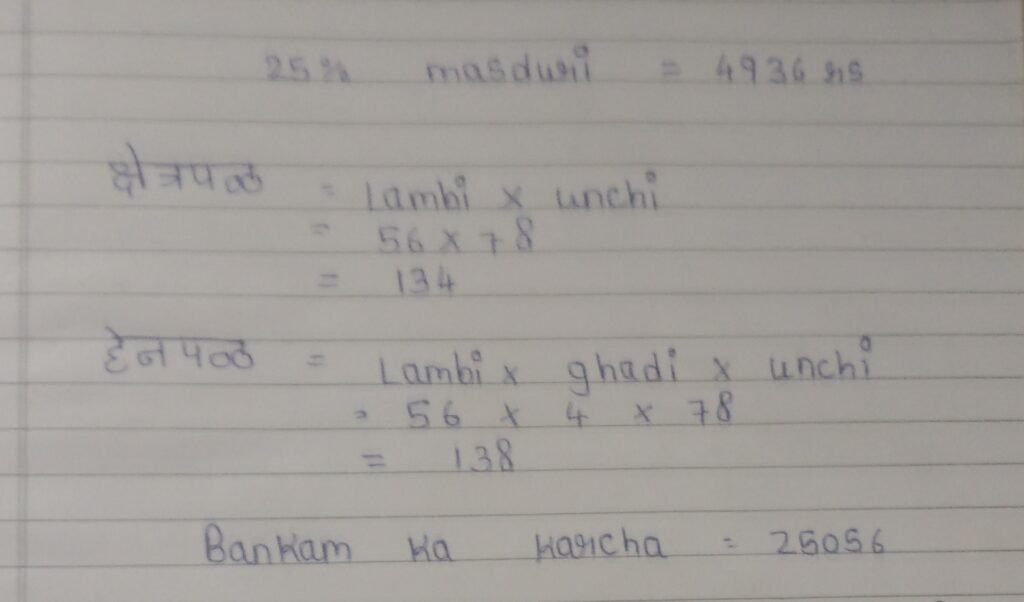

CONSTRUCTION

. 1) 40 kg chemical =500 rs

. 2) cement – 350 rs

3) cement sheet – 45 rs foot

. 4) welding rod – 400 packet

. 5) tupe-2×1 = 500

6) prahimar 250 rs litre

7) wadu 28 rs ak damal 3.5 foot dis

In its most widely used context, construction covers the processes involved in delivering buildings, infrastructure, industrial facilities, and associated activities through to the end of their life. It typically starts with planning, financing, and design that continues until the asset is built and ready for use.

Cement is mainly used as a binder in concrete and which isa a basic material for all types of construction .

. The techniques and industry involved in the assembly and erection of structures primarily those used to provide shelter.

The process where contraction build structure that serve a particular purpose .

In its most widely used context construction.

FRP

.Your entrance is an important first impression of your home. When guests enter your house for the first time, they are immediately given an impression of you and your lifestyle. The look of your front door can tell a lot about you. A well-designed front door sets the expectation for your home

door is a hinged or otherwise movable barrier that allows ingress (entry) into and egress (exit) from an enclosure. The created opening in the wall is a doorway or portal. A door’s essential and primary purpose is to provide security by controlling access to the doorway (portal).

a flat object that is used to close the entrance of something such as a room or building, or the entrance itself: the front door.

The different sides of the door handle are joined together by a long thin piece of metal called a spindle. When you turn the door knob (or press down on the handle) the spindle rotates and activates the latch mechanism to retract the bolt. This releases the door and lets you open it.

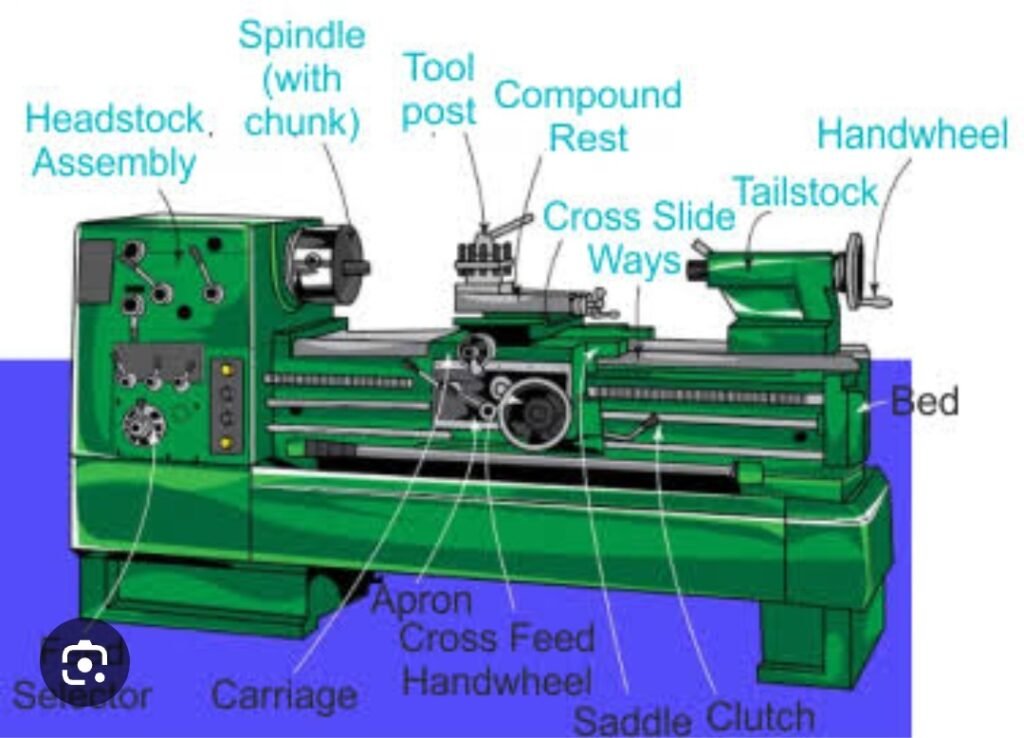

LATHE MACHINE

. A lathe is a machine tool used to shape wooden or metallic products. It furnishes a wooden or metal piece by rotating it about an axis while a stationary cutting tool keeps removing unwanted material from the workpiece to form the desired shape.

Full form of ‘lathe’ is Longitudinal Axis Tool Holding Equipment. … Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working.

lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

The main parts of the lathe are: (1) the bed, (2) the quick-change gearbox, (3) the headstock, (4) the carriage, and (5) the tailstock.

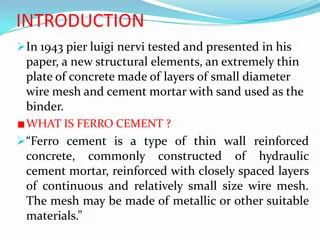

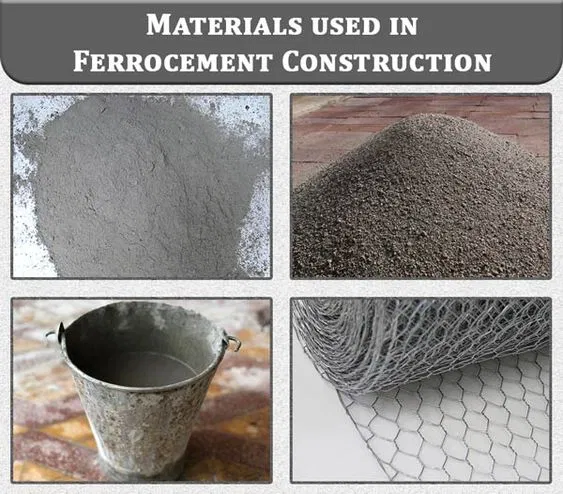

FERO CEMENT

Ferrocement or ferro-cement is a system of construction using reinforced mortar or plaster (lime or cement, sand, and water) applied over an “armature” of metal mesh, woven, expanded metal, or metal-fibers, and closely spaced thin steel rods such as rebar.

Ferrocement has high fracture resistance, tensile strength, flexural strength, toughness, impact resistance and fatigue resistance. It is a thin-wall type of reinforced concrete that includes best cement mortar layered with continuous and comparatively small diameter mesh.

Ferrocement is used to construct relatively thin, hard, strong surfaces and structures in many shapes such as hulls for boats, shell roofs, and water tanks. Ferrocement originated in the 1840s in France and the Netherlands and is the precursor to reinforced concrete.

Ferrocement consists of a cement-rich mortar reinforced with layers of wire mesh, sometimes with additional plain wire reinforcement for added strength. Tanks made of ferrocement are used in many countries for the collection and storage of water for drinking, washing, for animal use and irrigation.

The fineness of cement has an important bearing on the rate of hydration and hence on the rate of gain of strength and also on the rate of evolution of heat. Finer cement offers a greater surface area for hydration and hence faster the development of strength.

RCC COLOUM

n RCC Column is the vertical member that effectively takes load by compression. Basically, its a compression member as the load acts on columns longitudinal axis. The bending moment could occur because of wind, earthquake or accidental masses.

A reinforced concrete column is a structural member designed to carry compressive loads, composed of concrete with an embedded steel frame to provide reinforcement. For design purposes, the columns are separated into two categories: short columns and slender columns.

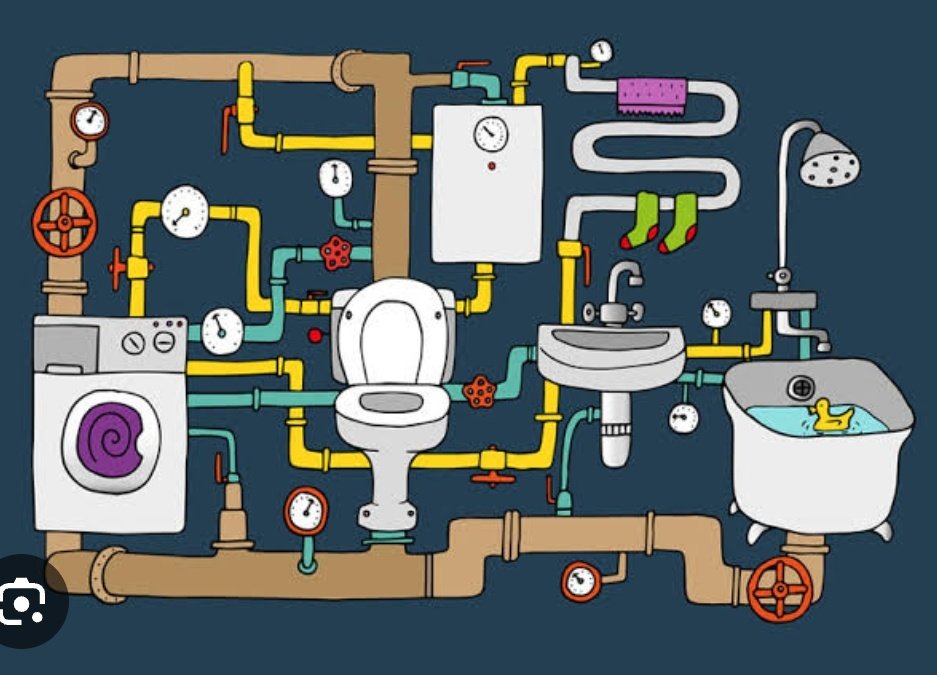

Plumbing

plumbing, system of pipes and fixtures installed in a building for the distribution and use of potable water and the removal of waterborne wastes. It is usually distinguished from water and sewage systems that serve a group of buildings or a city.

plumbing, system of pipes and fixtures installed in a building for the distribution and use of potable water and the removal of waterborne wastes. It is usually distinguished from water and sewage systems that serve a group of buildings or a city.

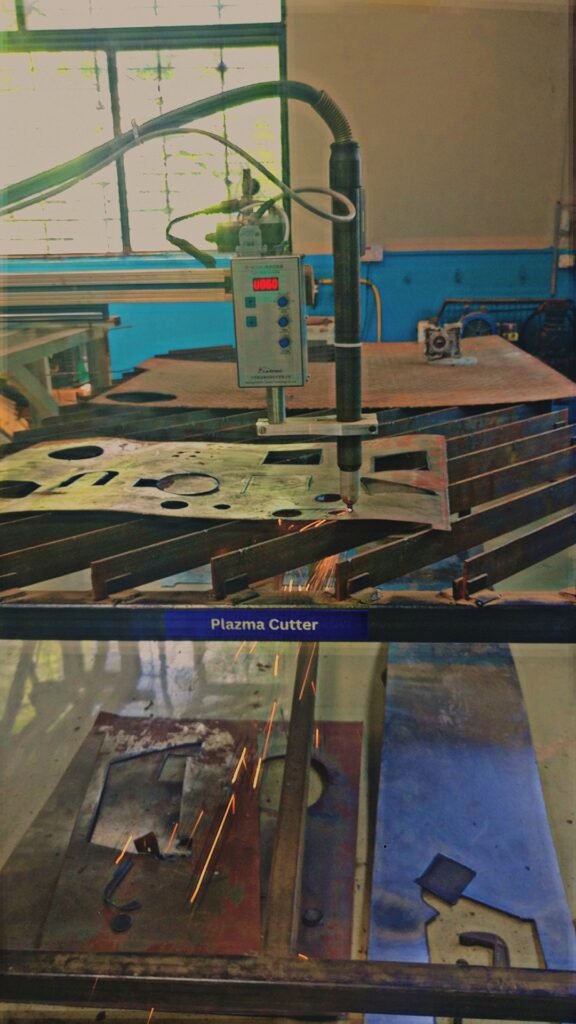

PLAZMA CUTTER MACHINE

Sep 29, 2024 | Uncategorized

. Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well.

The basic principle is that the arc formed between the electrode and the workpiece is constricted by a fine bore, copper nozzle. This increases the temperature and velocity of the plasma emanating from the nozzle. The temperature of the plasma is in excess of 20 000°C and the velocity can approach the speed of sound.

How useful is a plasma cutter?Plasma Cutters Can Cut Almost Any Form of MaterialIf you wanted to cut various forms of metal (plate, tube, angle, beam, grating), you would need multiple different types of saws or shears. A plasma cutter can do it all.

Plasma means: When in a liquid or a gas the number of free charge carriers is so large that charge carriers affect the physical properties of the medium substantially. When electromagnetic interactions between the charged particles take place.

Carpentry

. Carpentry involves cutting, shaping and fastening wood and other materials together to produce a finished product. Preparation of joints is one of the important operations in wood work. Joinery denotes connecting the wooden parts using different points such as lap joints, mortise and T- joints, bridle joints, etc.

A Carpenter is a construction professional who works with construction crews to build, adjust and repair wood frameworks in various construction projects. They work with their hands, using tools to build and install frameworks that last a lifetime!

The Carpenter Short is a standard-fit knee-length short constructed from 100% cotton dirty wash denim. Made with robust workwear qualities, it features a reinforced waistband and triple-stitched leg seams for durability. It is designed with a zip fly, front rounded pockets, a coin pocket, and two back patch pockets.

Carpentry is a precision skill which requires accuracy in measuring and cutting so that everything fits into the construction project smoothly and no wood is wasted.