Jun 16, 2022 | Uncategorized

एल डी आर (लाइट ͫडपेंडेंट रेसिस्टर)

हमारे चारो तरफ बहुत सारे ऐसे डिवाइसेज होते हैं जो कि लाइट के इंटेंसिटी को डिटेक्ट कर

के काम करते हैं. Example के तौर पर अगर आप अपनेमोबाइल फोन की बात करें तो

आप क्या आपने कभी सोचा कि आपके फोन की ब्राइटनेस ऑटोमेटिक मोड कैसे कम लाइट

में खुद ब खुद कम हो जाती है और जब ambience लाइट काफी ज्यादा होती हैया धूप

होती हैऔर जब आपको देखने में तकलीफ होती है तब आपका फोन कैसे अपने आप

ब्राइटनेस को बढ़ा देता है? और इस तरह कम लाइट और ज्यादा लाइट मेंभी आप अपने

फोन में क्लियर देख पाते हैं. ऐसा लाइट सेंसर होने की वजह से ही संभव हो पाता है. फोन में

एक लाइट सेंसर होता हैजो बाहर का illumination continuously मॉनिटर करता रहता

हैऔर एक प्रोग्राम के according उसे कंट्रोल करता है.

आज हम देखेंगे कि कैसे एक लाइट सेंसर काम करता है और कैसे उसे इस्तेमाल कर सकते हैं.

लाइट सेंसर क्या है ?

Sensor का काम है कसी भी physical

quantity को electrical quantity में

कन्वर्ट करना ताकि हम उसे electronic

form में प्रोसेस कर पाए. इसी तरह लाइट

सेंसर, लाइट की एनजर्जी को इलेक्ट्रिकल

सिग्नल में कन्वर्ट करता है. अलग-अलग

ऐप्लिकेशन केहिसाब से मार्केट में अलग-

अलग तरह के लाइट सेंसर उपलब्ध है. पर

सबसेजो simple और inexpensive सॉल्यूशन हैं वह LDR

LDR क्या है?

Light Dependent Resistor लाइट ͫडपेंडेंट

रेिजस्टर जैसा ͩक नाम सेिक्लयर हैएलडीआर पर

जैसे-जैसेलाइट यानी illumination का वेǐरएशन

होता है, वैसेवैसेएलडीआर अपना रेिजस्टेंस vary

करता है. जब LDR पर illumination नहȣं होता

तो यह काफी ज्यादा रिजस्टेंस (MegaOhm)

ऑफर करता है. जैसे-जैसेएलडीआर के ऊपर लाइट

डालȣ जाती हैइसका resistance धीरे-धीरेघटने

लगता है. एक सेंसर के ͧलए यहȣ सबसेज्यादा

इंपॉटर्टेंट बात हैͩक ͩकसी भी इलेिक्ट्रकल क्वांǑटटȣ का

बदलाव होना. Resistance के बदलाव को हम

अपने according configure करके अलग अलग

एप्लȣके शन मेंइस्तेमाल कर सकतेहैं

3D PEINTER

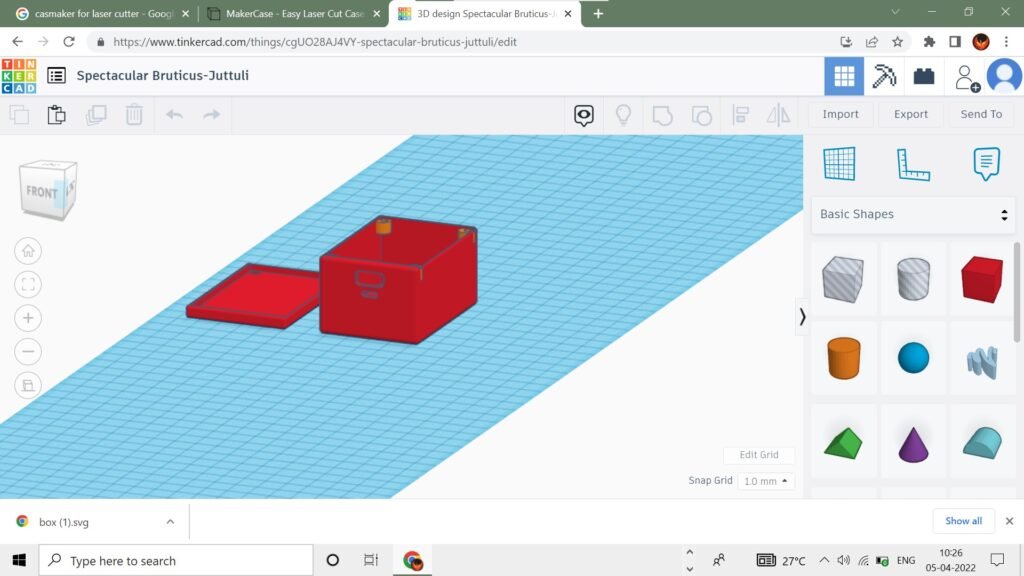

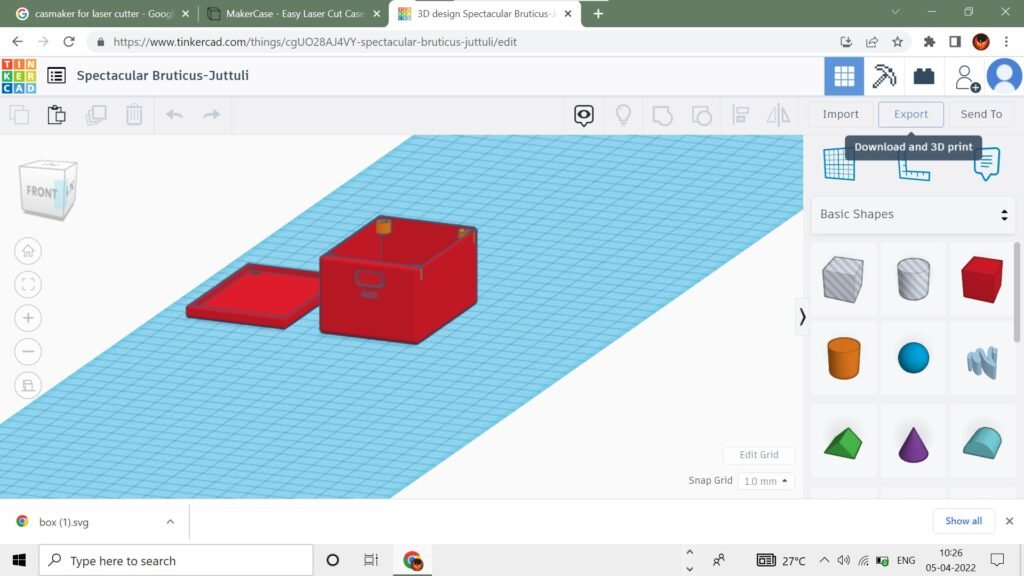

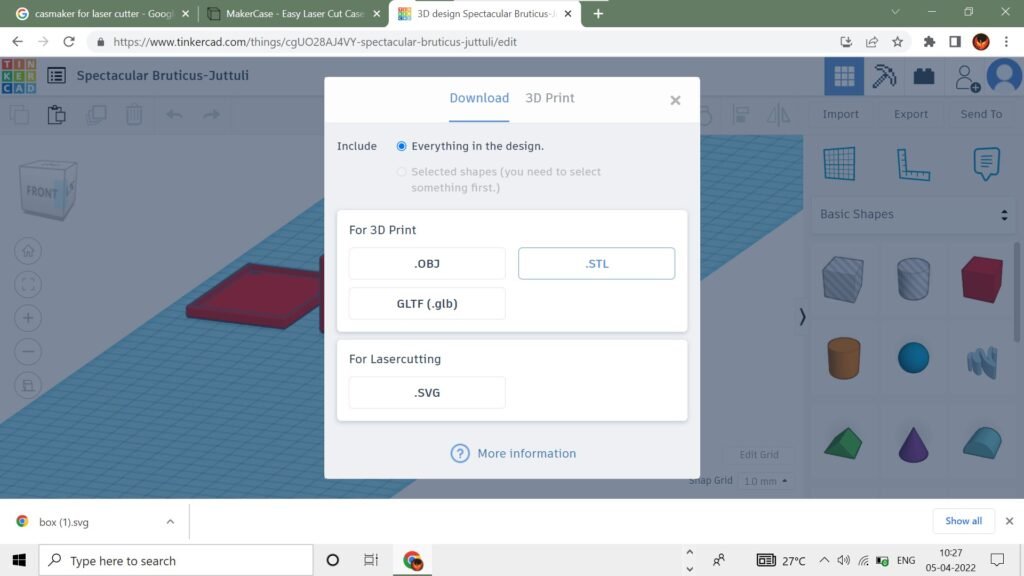

- do the desigmning in tinkercad software or any cad software

- https://www.tinkercad.com/

4. then export the file in stl format

5. then open the factory software

6.

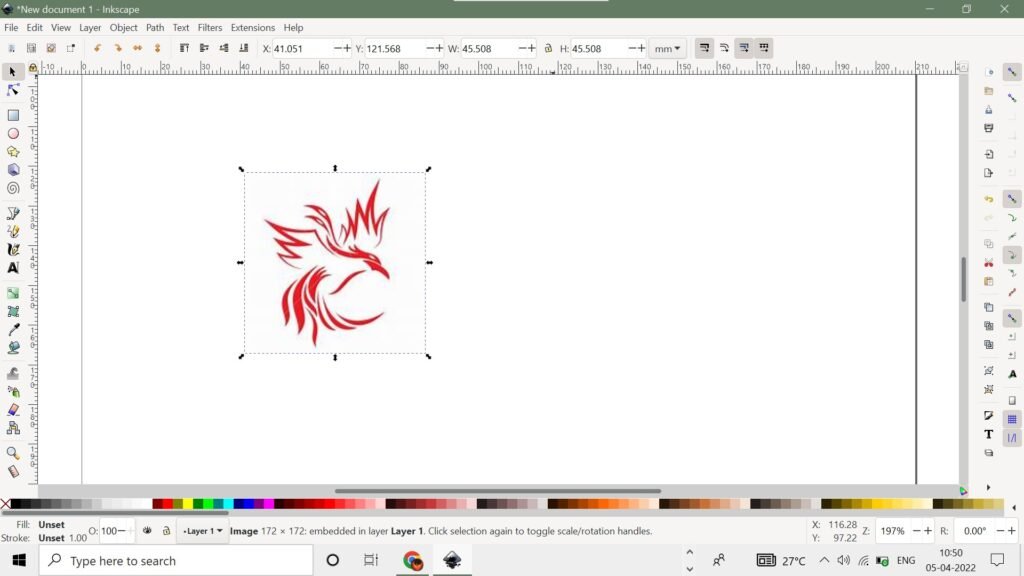

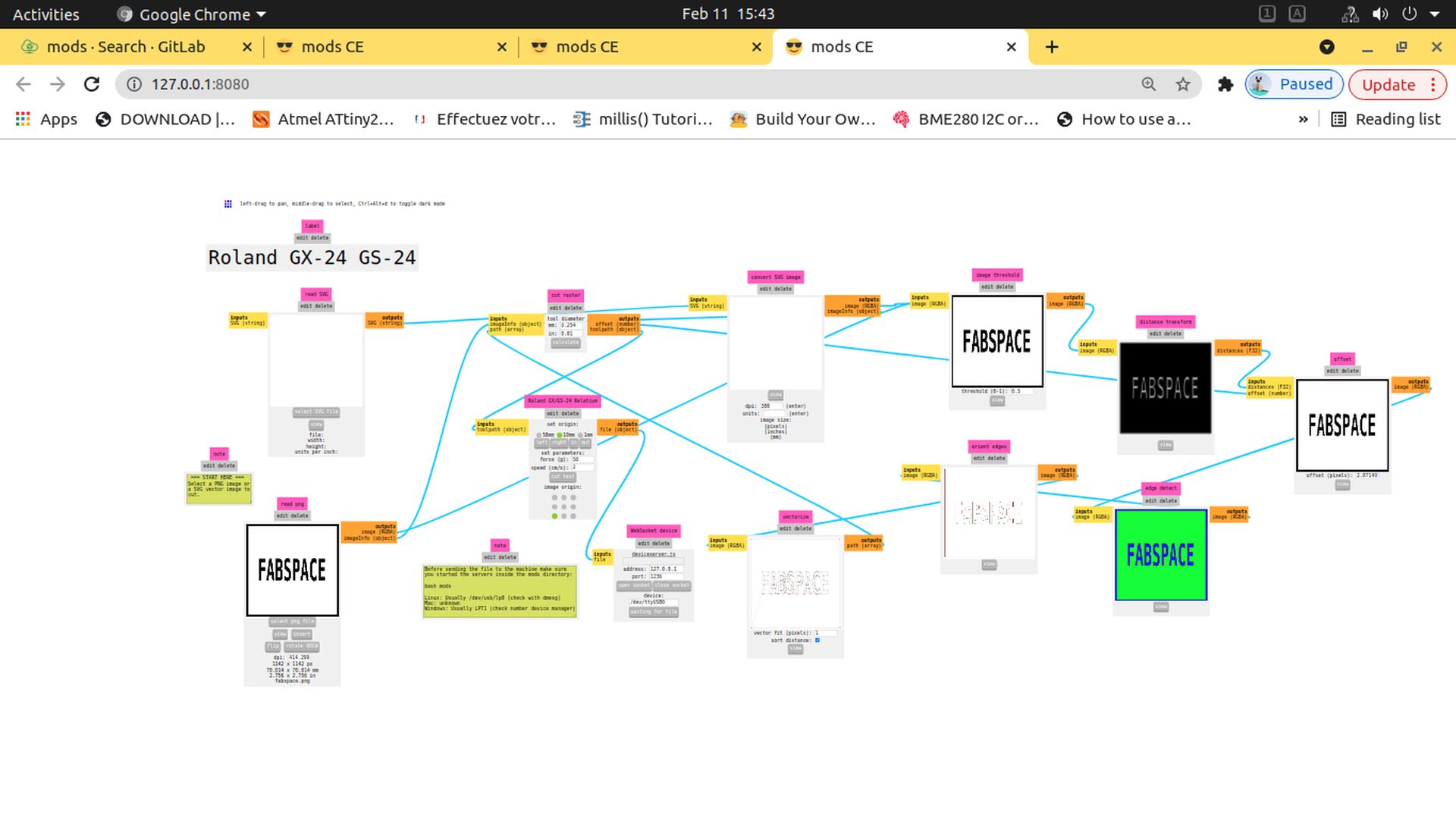

2.VINYL CUTTER

- i got you covered baby

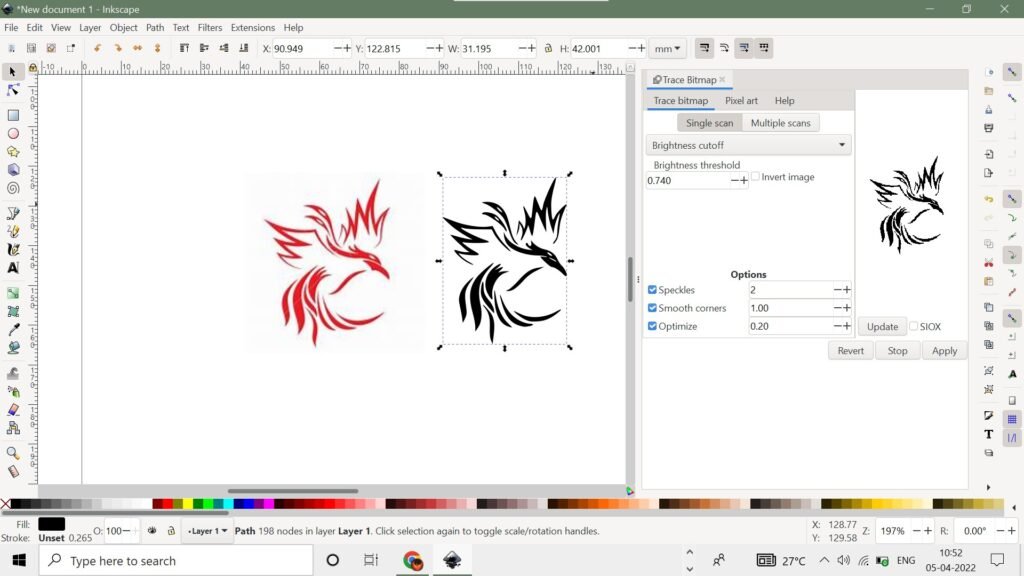

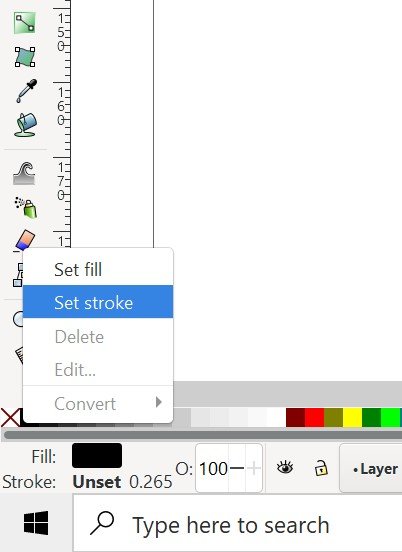

- design the file in inscape

- https://inkscape.org/

- open image in inscape

5. go to paths and trace bitmap

6. seprate the image with the bitmap

7. delete the image

8. and set stroke and hit the cross icon to cut the paint on it

9. export the file in png image file format

10. go to mods ce nodes

http://www.modsproject.org/

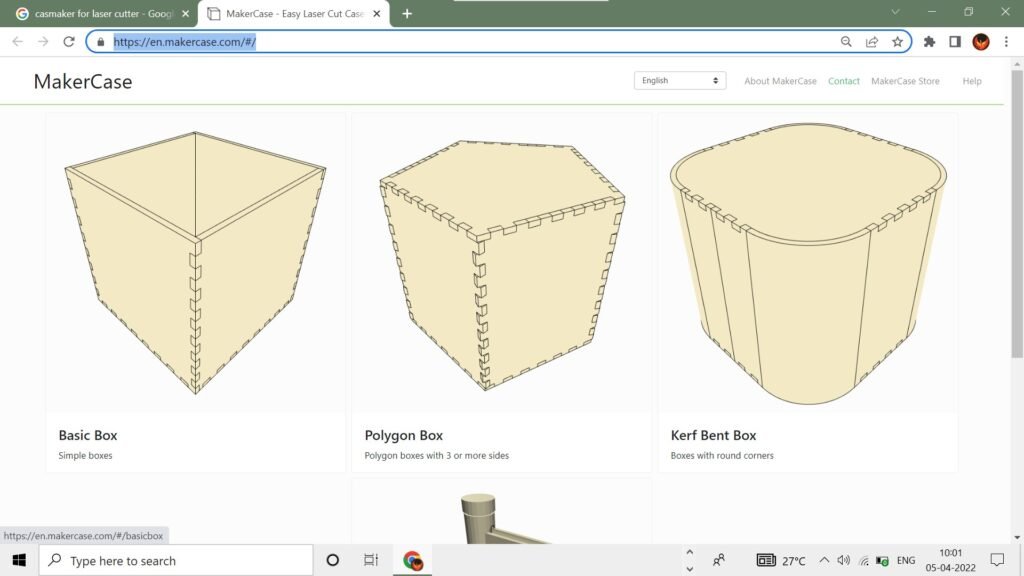

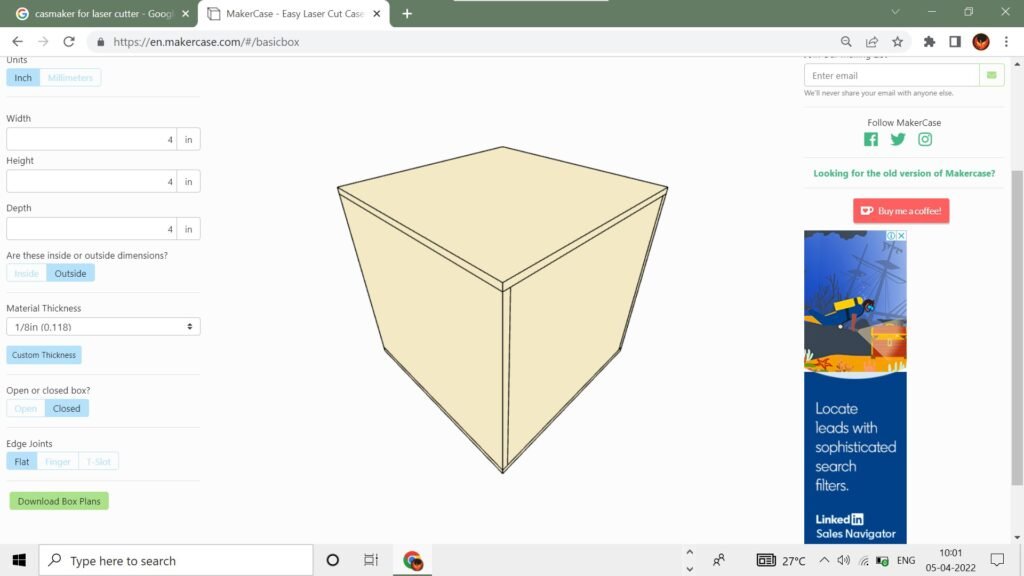

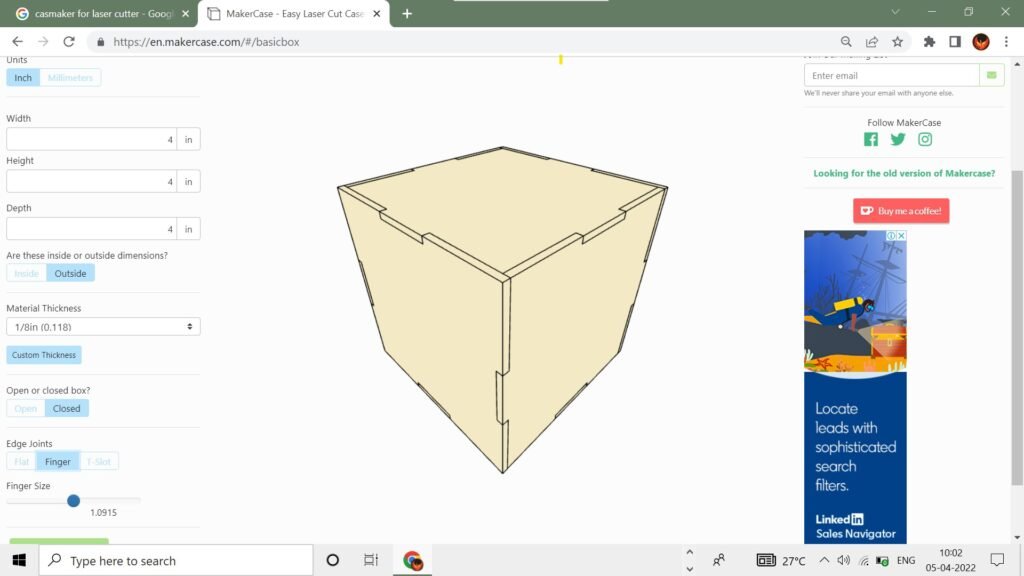

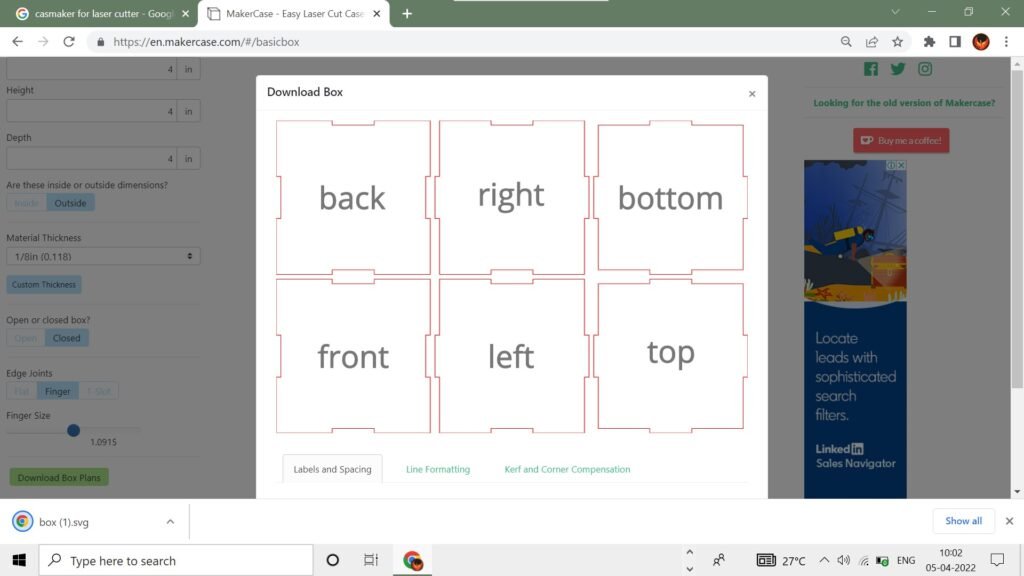

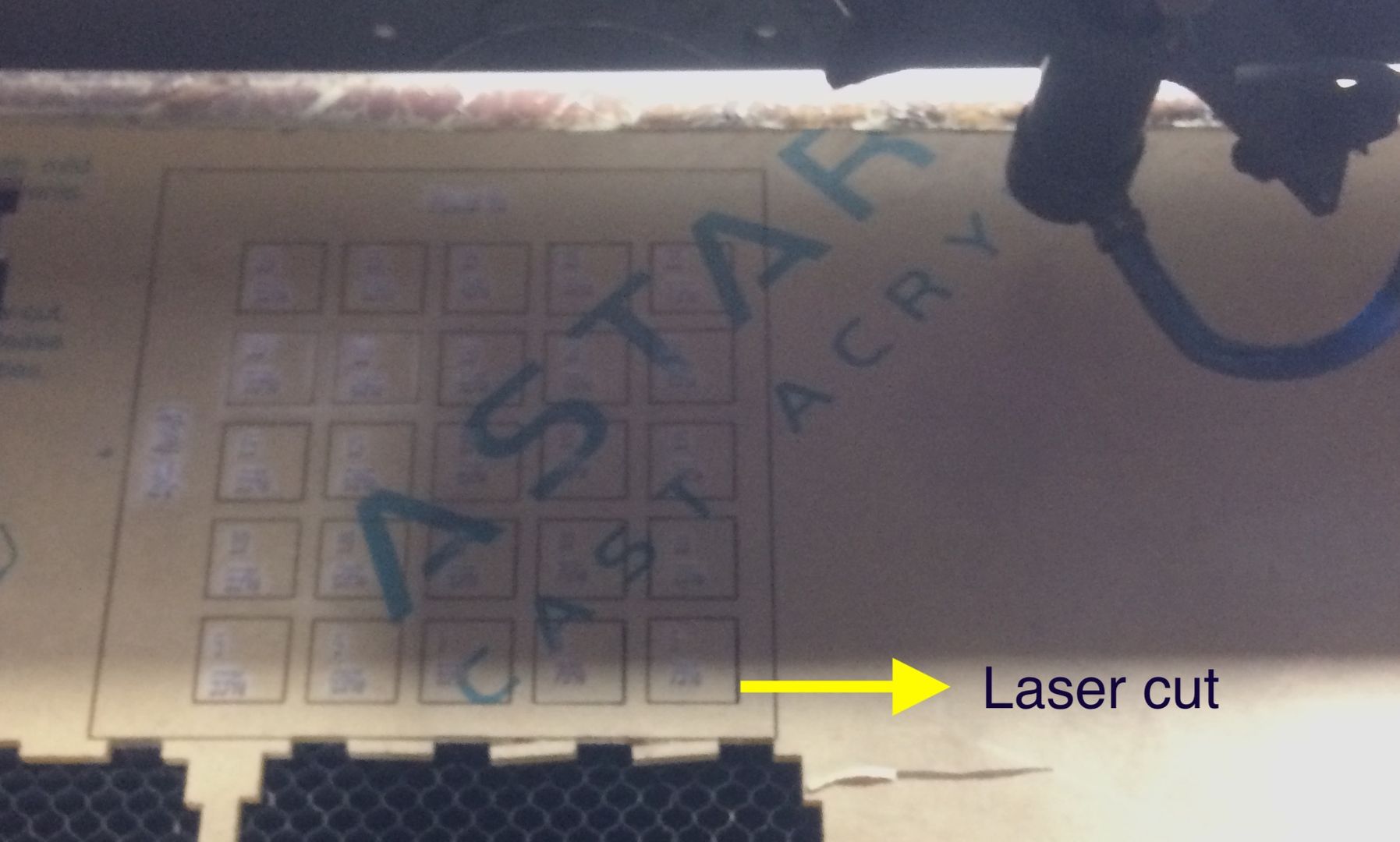

3 LASER CUTTING A BOX

today I will teach you a simple method to cut a box on laser cutter wity the hinges which are known as fingers

- head over to makercase for laser cutte

- link = https://en.makercase.com/#/basicbox

4. select the type of box that you want to make in my cae it wa sd the basic box

5. in here seleclct the appropriate metrics in my case or reccomended is mm

and then adjust the values till desired box is achived

6. select the closed box or open box

7. then selest the fingers and the no of fingers by sliding the slider

8. download the file in SVG file format

Exif_JPEG_420

Exif_JPEG_420

Exif_JPEG_420

fab lab machine in use ther use

3D printing machine

vinay cutter machine

leazer cutters machine

grocubator

मका हायड्रोपोनिक्स प्रोजेक्ट घेतला होता तर मक्याला मोड आले नव्हते. म्हणून grocubator चा वापर केलं होत. पण मका खराब असल्या मुळे मोड आले नाही.

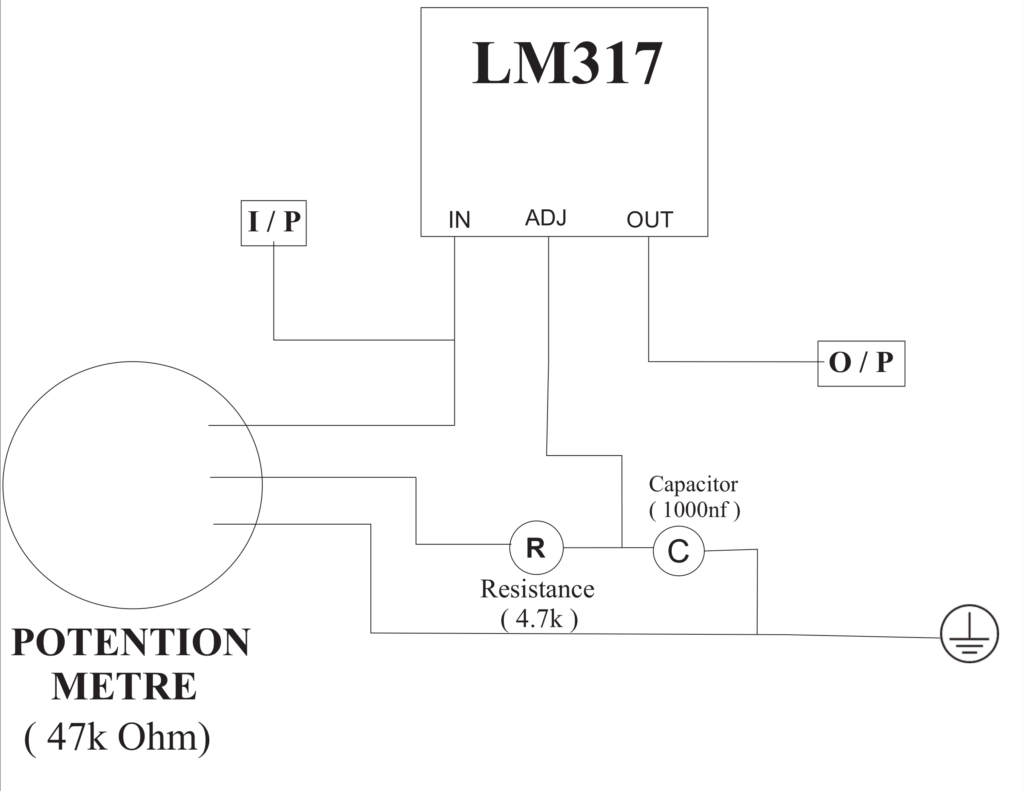

Voltage Regulator

Material :

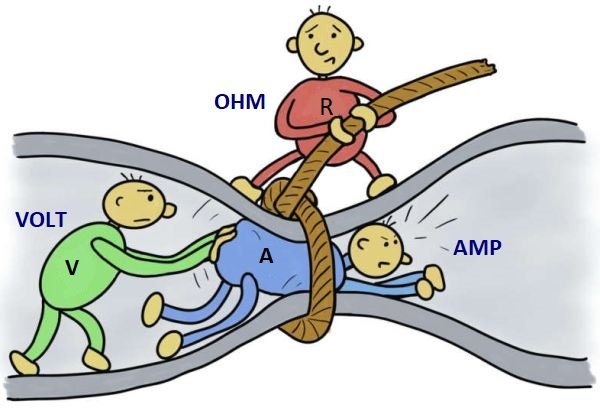

RESISTANCE ( 4.7K OHM )

- Resistance is the opposition that a substance offers to the flow of electric Current.

- The standard unit of resistance is the Ohm.

- विद्युत मंडळात विद्युत प्रवाह म्हणजेच इलेक्ट्रॉन्सच्या वहनाला जो घटक अडथळा निर्माण करतो त्यास विद्युतरोध असे म्हणतात

- विद्युतरोध मोजण्याचे एकक ओहम (Ω) आहे.

Resistance Colour Code Link :

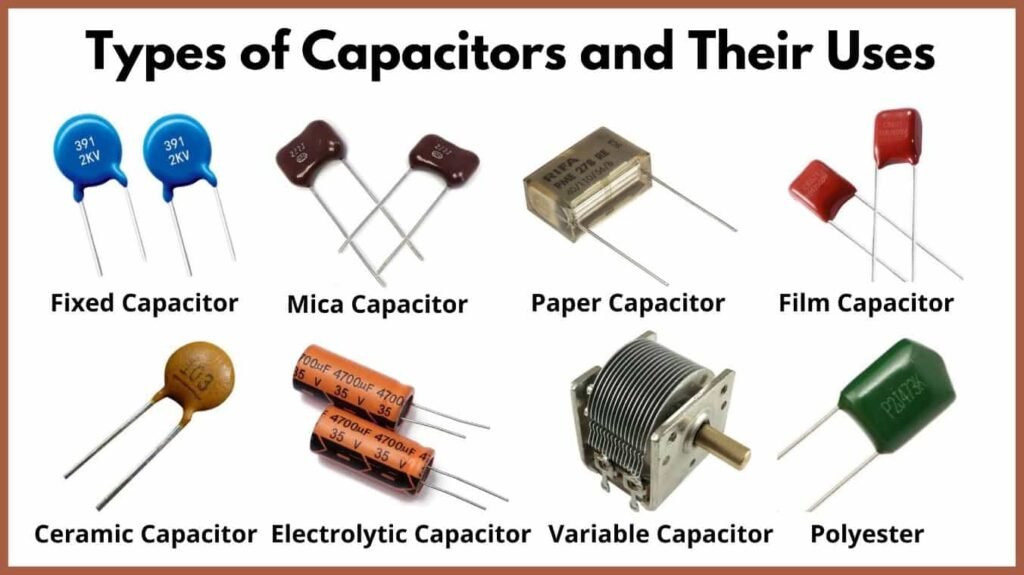

CAPACITOR ( 100NF )

- A capacitor is a device that stores electrical energy in an electrical field.

- The unit of electrical capacitance is the farad (abbreviated F).

Function:

1) Charging and discharging electric charges

2) Keeping the voltage at the same level

Types OF Capacitor :

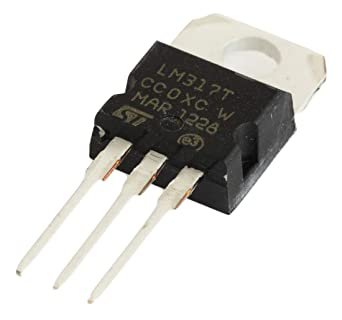

LM317 IC ( TRANSISTOR )

- The transistor is a semi conductor device used to control and generating an electrical signals.

- LM317 is a voltage regulator IC . that IC work dropout voltage .Voltage RegulatoRegul

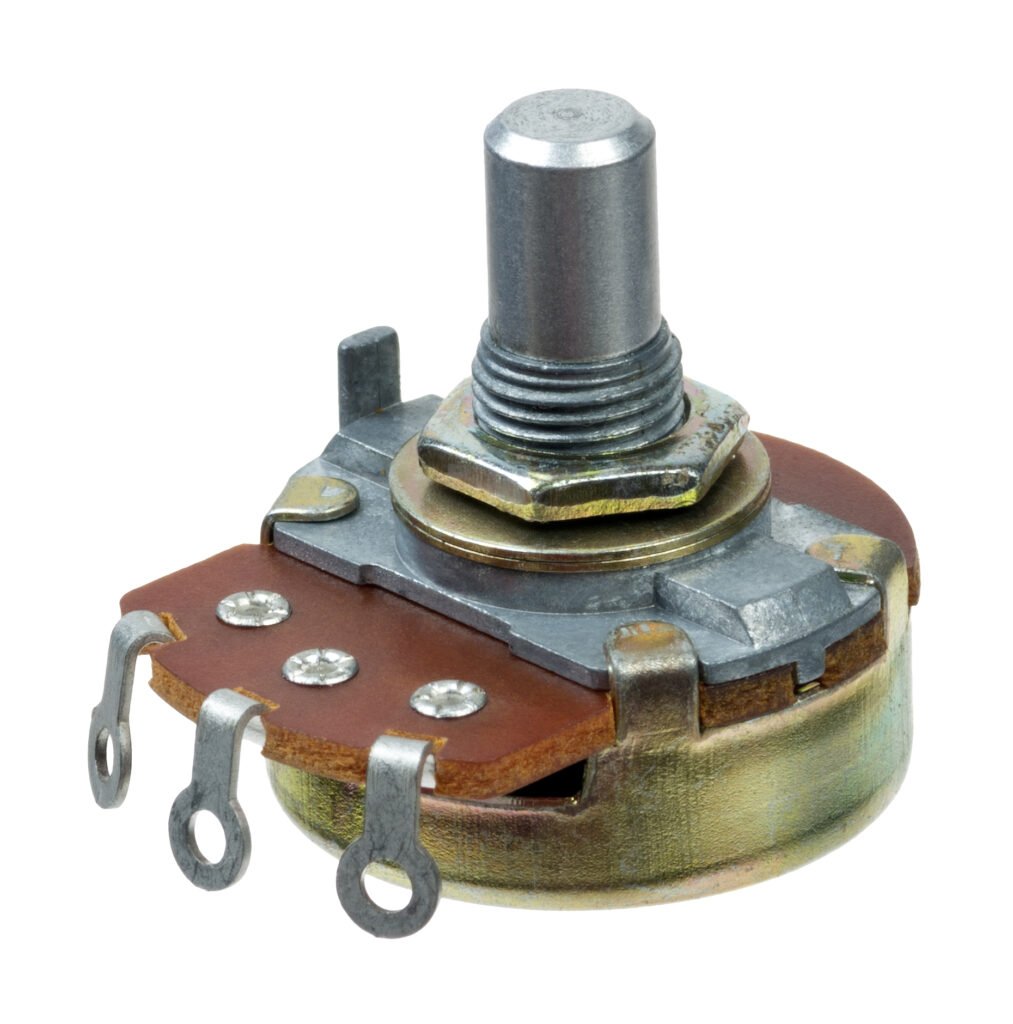

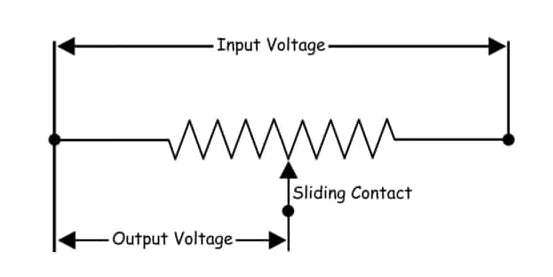

POTENTIAL METRE

A potentiometer is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider

Circuit Diagram

Connection

Final

Final

OMPUTER CONTROLLED CUTTING

OBJECTIVE

Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways.

Account for the lasercutter kerf.

Cut something on the vinylcutter.

INTRODUCTION

TOOLS AND MACHINES

A tool is a device or implement, especially one held in the hand, used to carry out a particular function. – Oxford Languages.

Eg:- Knife, Chisel

A machine is an apparatus using mechanical power and having several parts, each with a definite function and together performing a particular task. – Oxford Languages.

Eg:- Coffee maker

Both a tool and a machine are designed for a specific purpose and make the jobs easier to perform.

Eg:- Knife – Used to cut things.

Sewing Machine – Used to stitch clothes.

In this week we were given a brief introduction on Lasercutter, Vinylcutter, Knifes. We were encouraged to build a construction kit using different joints. The materials that could be used are given below.Cardboard

MDF

Acrylic

Plywood

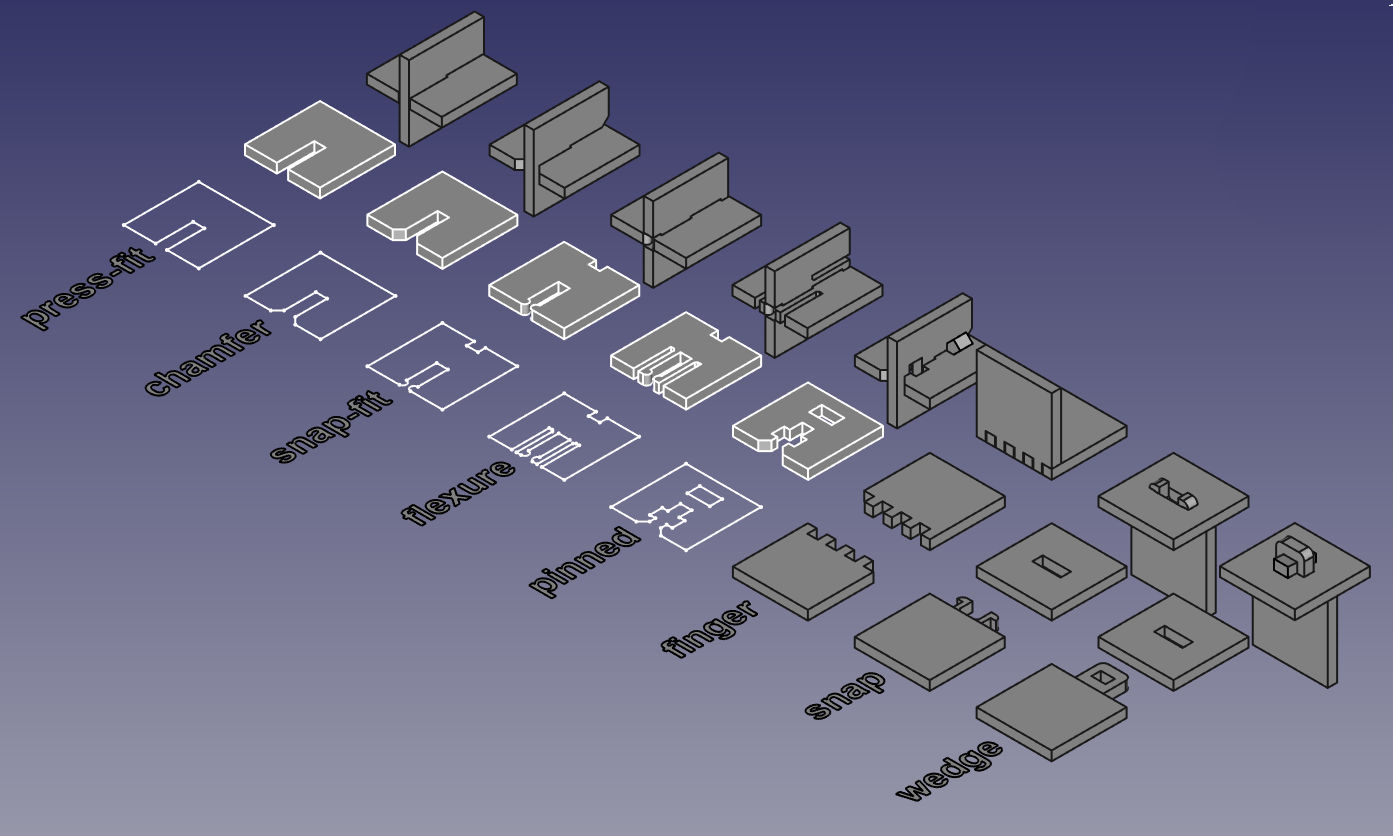

DIFFERENT TYPES OF JOINTS

Press-fit

Chamfer

Snap-fit

Flexure

Pinned

Finger

Snap

WedgeThe image below shows the different kinds of joints.

source – fabacademy

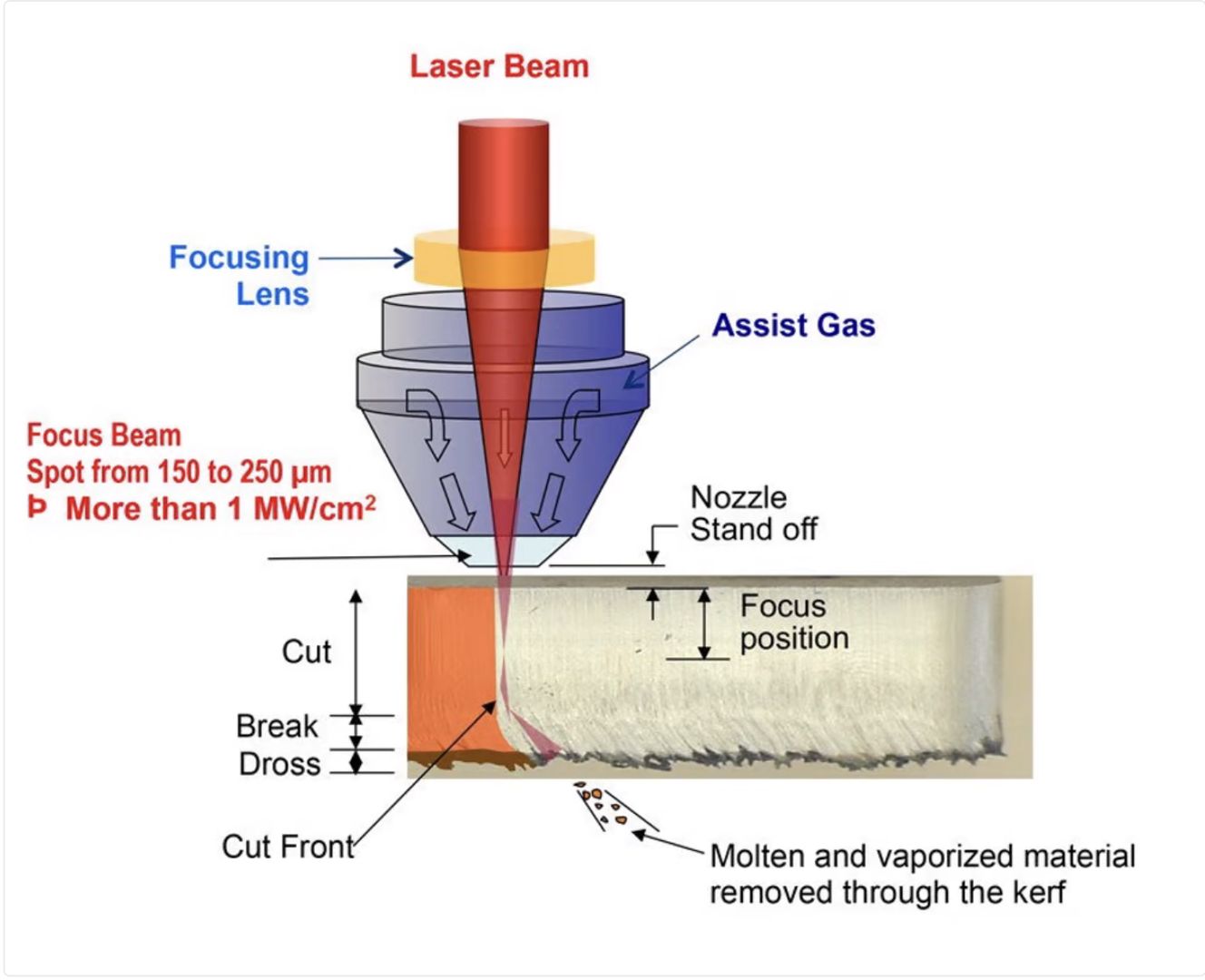

LASERCUTTER

“LASER”- Light Amplification by the Stimulated Emission of Radiation. Lasers are used in a variety of applications and fields like medical surgeries, weaponries, guiding systems etc.

They are of various types

Gas Laser

Fibre Laser

Solid-State Laser

Liquid Laser Etc. Laser are also used achieve pin-point accuracy.

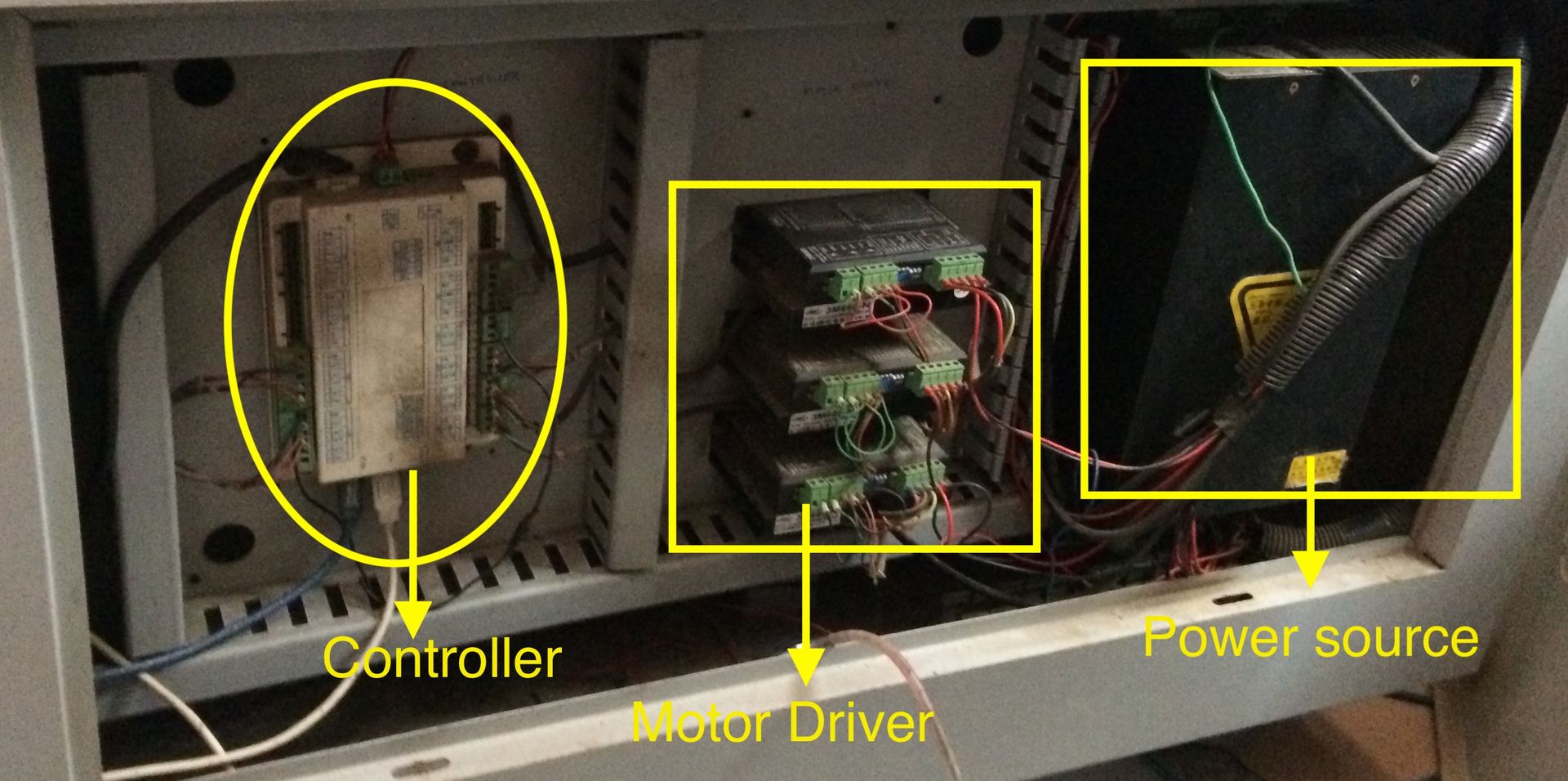

It consists of mainly three parts.

Gain-medium

Power source

Optical lens

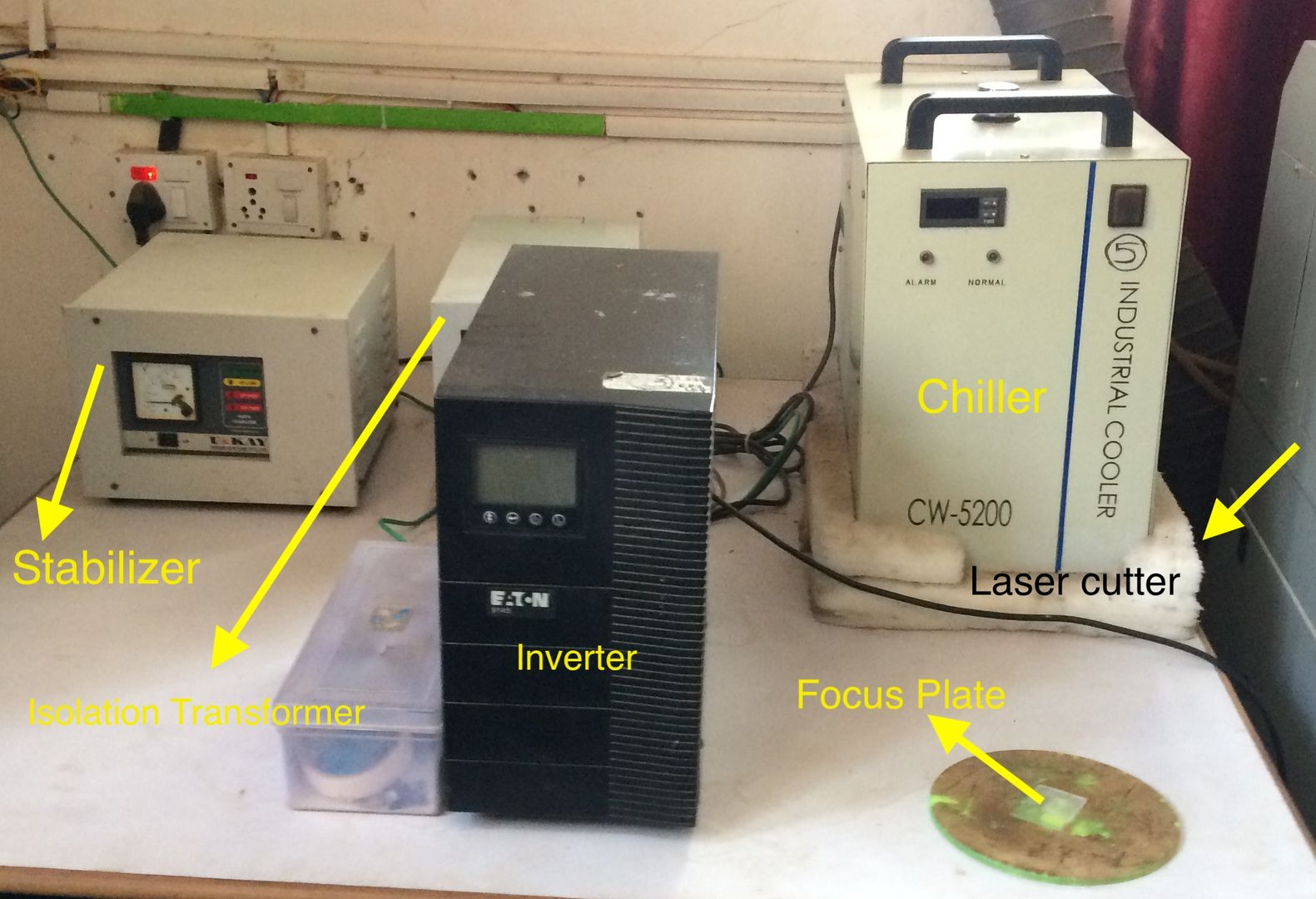

The laser cutter that we used was a CO2 laser which is categorised into gas lasers Listed below are its specifications.

Axis – 3 axis

Power – 80 W

Focus -8 mm

Speed- 300 mm/s

source – Internet

GAIN-MEDIUM

It is the medium used to excite electrons to a higher state of charge that has to generate a beams of laser

POWER SOURCE

They provide external source of energy which is used to excite the gain medium.

OPTICAL LENS

These are special lens used for focusing or concentrating the beam created to cut or scan the required material.

SOFTWARES USED

- Fusion 360

- RDWorks

SAFETY INSTRUCTIONS

- Make sure all the experiments performed are under the supervision of the lab instructor.

- Read the instruction manual.

- Where necessary safety equipment.

- Have full concentration on the performing operations.

- Stay near the laser cutter while cutting or performing an operation.

- Do not cross the red line while on an ongoing process.

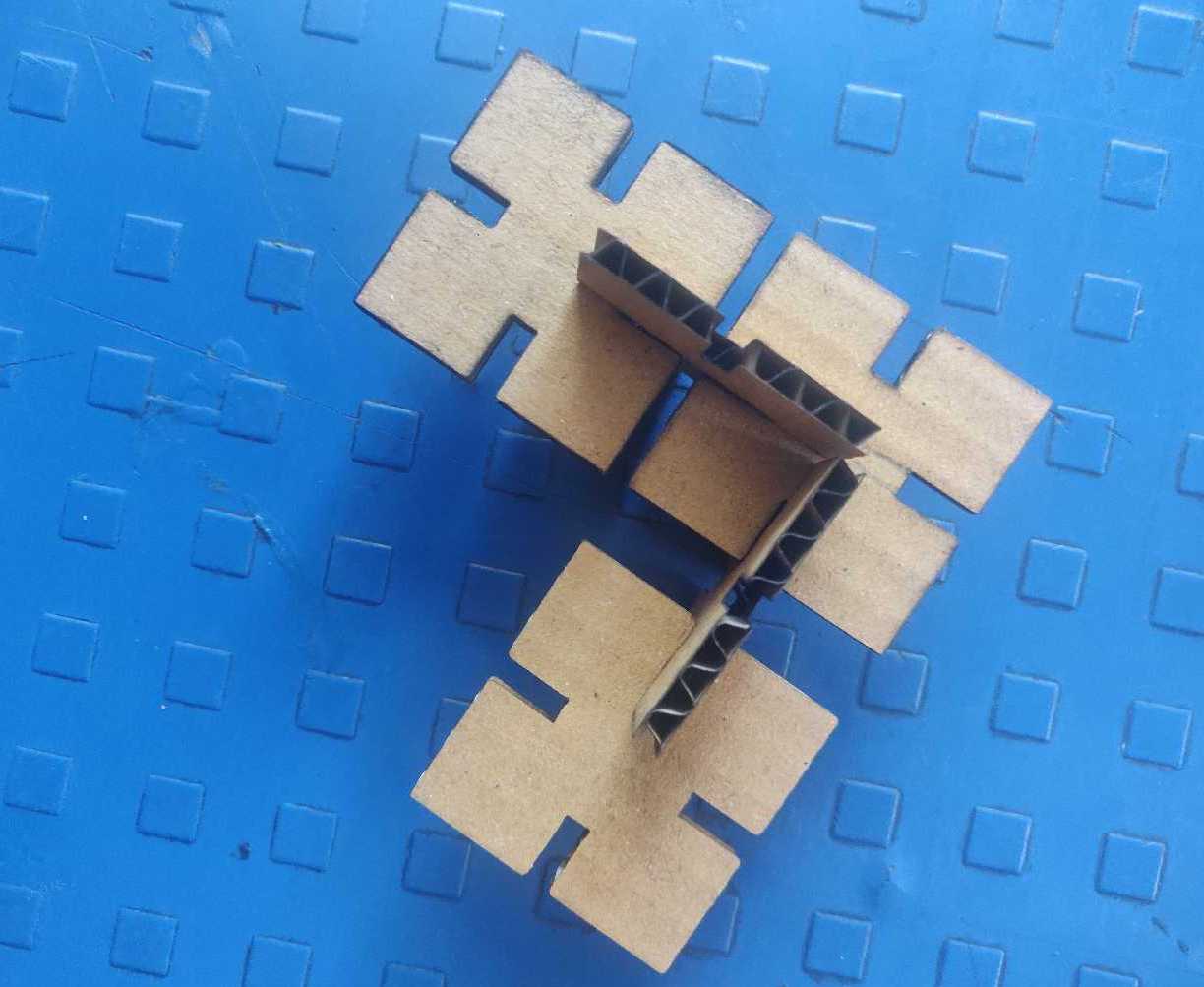

CONSTRUCTION KIT

For this weeks assignment I had to design a construction kit and for that I first tried to search over the internet what people have done.

I even had took a peak at my fellow classmates who were doing something of their own. I was not a creative guys so I thought of keeping the construction kit made up of simple shapesbr First I tried out Four shpars evnetually that failed then I went with only two. A square and a circle this allowed me to build something of a sorts cirles could act as wheels and bases and squares could act as a structure.

Then I chose is sizes arbitarily through trial and error through my failures I learnt that a there is no perfect size and its the perception of our thinking that appreciates it.

In my failure section I have some photos of a triangle, square etc. There I was able to find out that the size of the shapes or building block could tbe smaller this means that we could save cardboard by altering the size to few millimeters.

Through my success I intend to show that a press-fit construction if done perfectly could give a nice build.

DESIGNING IN FUSION 360

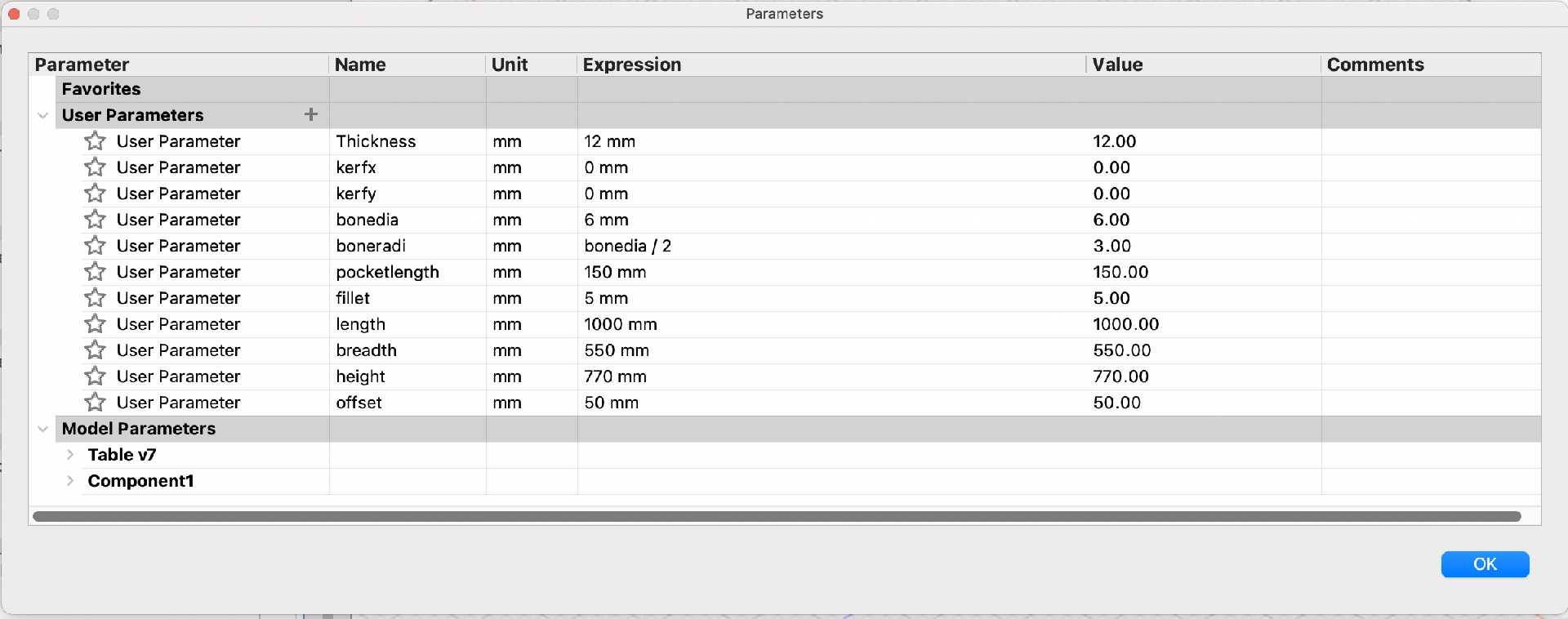

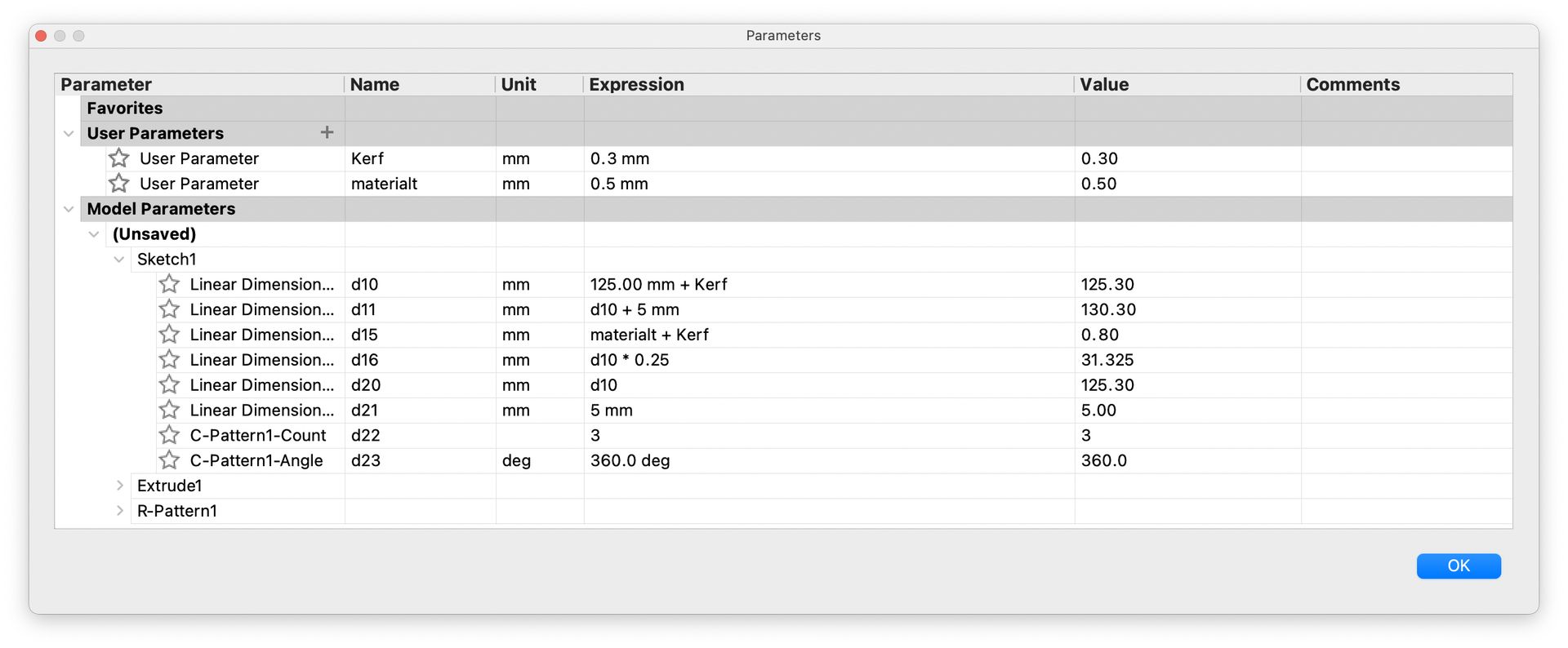

PARAMETRIC DESIGN

Parametric design is just used to make a design alot more dynamic. It is one of those key feature in CAD / CAM softwares that enables designer,architects,engineers to build 3D model very easily.

Parametric design simply means that instead of some arbitary value to be set on a design we are going to assign different parameters eg:- Thickness, Height, Width etc.

In Fusion 360 its very easy to set paramentric design fuctions. We could define a function and give in some values later these values could change over time to adjust the design.

To set parametric values in fusion goto the Modify tab at the toolbar and click Change parameters.

You could set different parameters like length, kerf, thickness etc.

The most important use this feature is in CNC machining where the thickness of a material decides the slot height.

Example :- Thickness of Plywood even though the rated thickness of plywood is 12mm it could range from 10.5mm to 12.5mm to account for this thickness we use parameteric design. These could be defined as parameters and then be given as arbitary value.

Eventually the design also adjusts according to the changes values.

KERF

It is the material removed by the cutting tool.

The image below also shows the kerf set in the design.

FAILURES

The Cardboard was uneven in thickness but couldn’t get the press fits right.

Below is an image showing a press fit of different shapes with slot measurements in paramentric design.

SUCCESS

Finally I built a construction kit It was very small and two shapes this configuration gave me a bit of ease while cutting the cardboard since I had to only cut out two shapes with multi quantities.

So Using the construction kit I created a bike that resembles a space pod from the tron series.

The image shows a prper press-fit construction of my work that is.

Below You can see the in the image of a bike from tron series.

Later I created a directional arrow sign so that it could be used to point to something.

Some other pictures of the construction kit.

VINYL CUTTER

A machine which is used to cut vinyl paper into different shapes or pieces is known as a vinyl cutter.

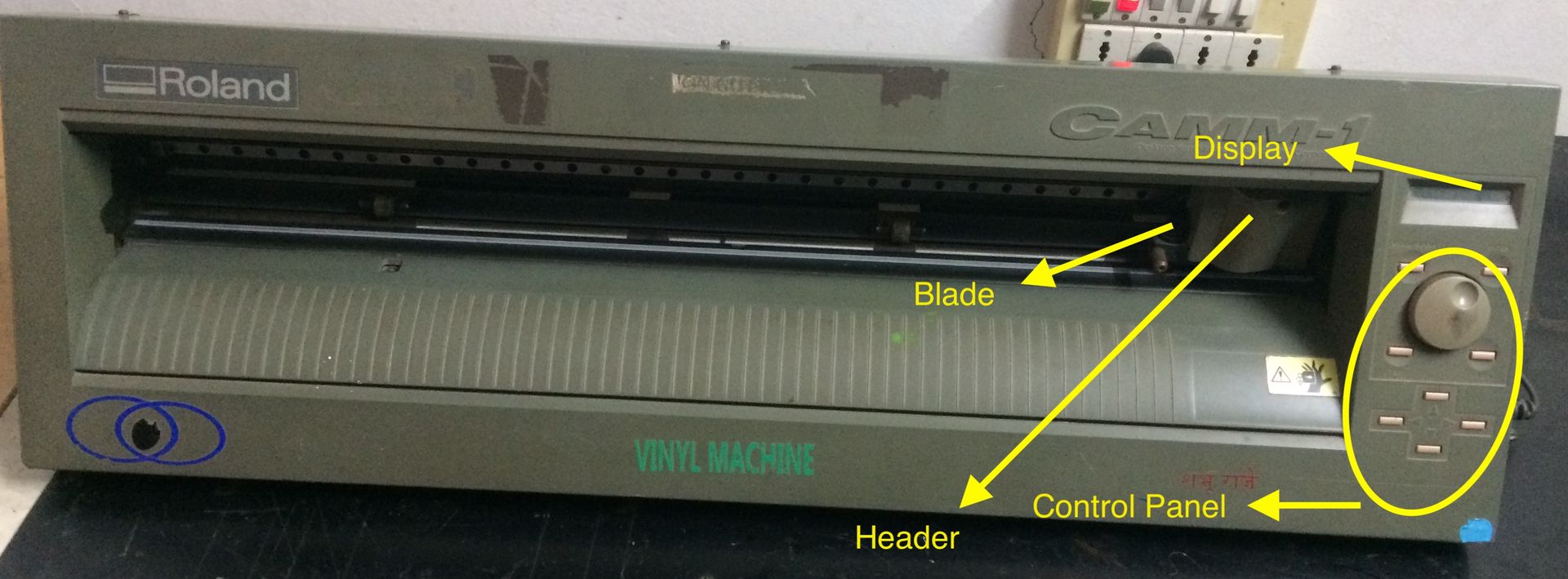

Roland is one of the manufacturer of vinyl cutter. At our lab the Roland CAMM-1 CX24 is used to cut vinyl to create different types of stickers.

It has many different parts that didn’t capture my attention so I’ll be inserting a manual of the same.

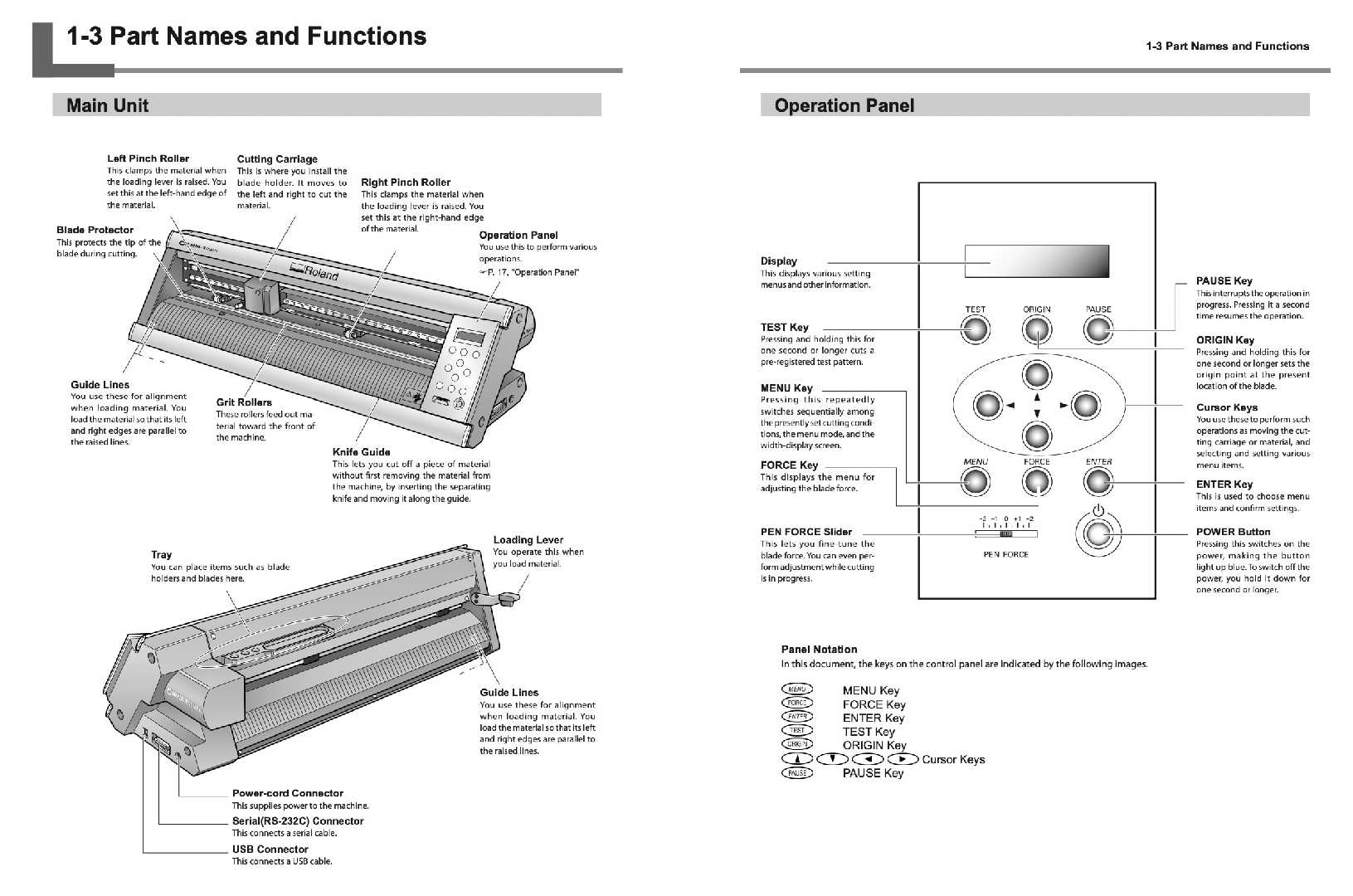

The user mannual is given below. Please note that the lab has an older version of the Vinyl Cutter but we are using the mannual of the latest one since its backwards compatible. A page of the User mannual of the vinyl cutter.

A page of the User mannual of the vinyl cutter.

The link to download the user mannual is here.

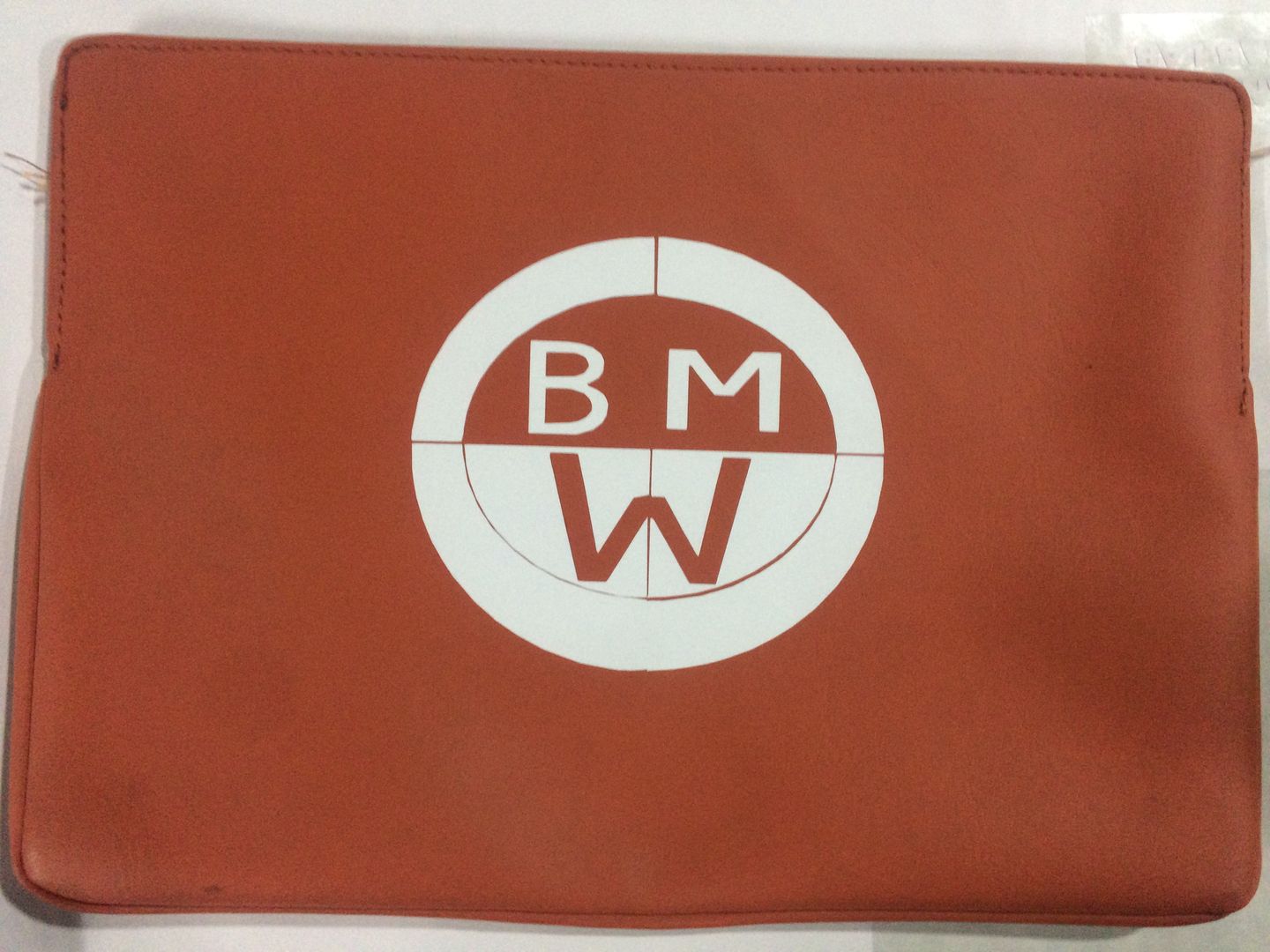

CUTTING SOMETHING ON VINYL CUTTER

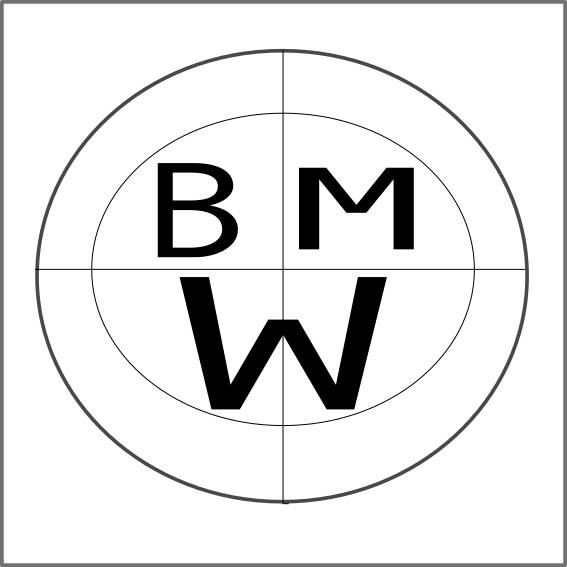

As the part of the assignment we were asked to cut something on a vinyl cutter. I decided to make a custom sticker for my laptop cover in the process. It was fun! and eventually learnt how to use the cutter correctly and got a brief walkthrough of mods also.

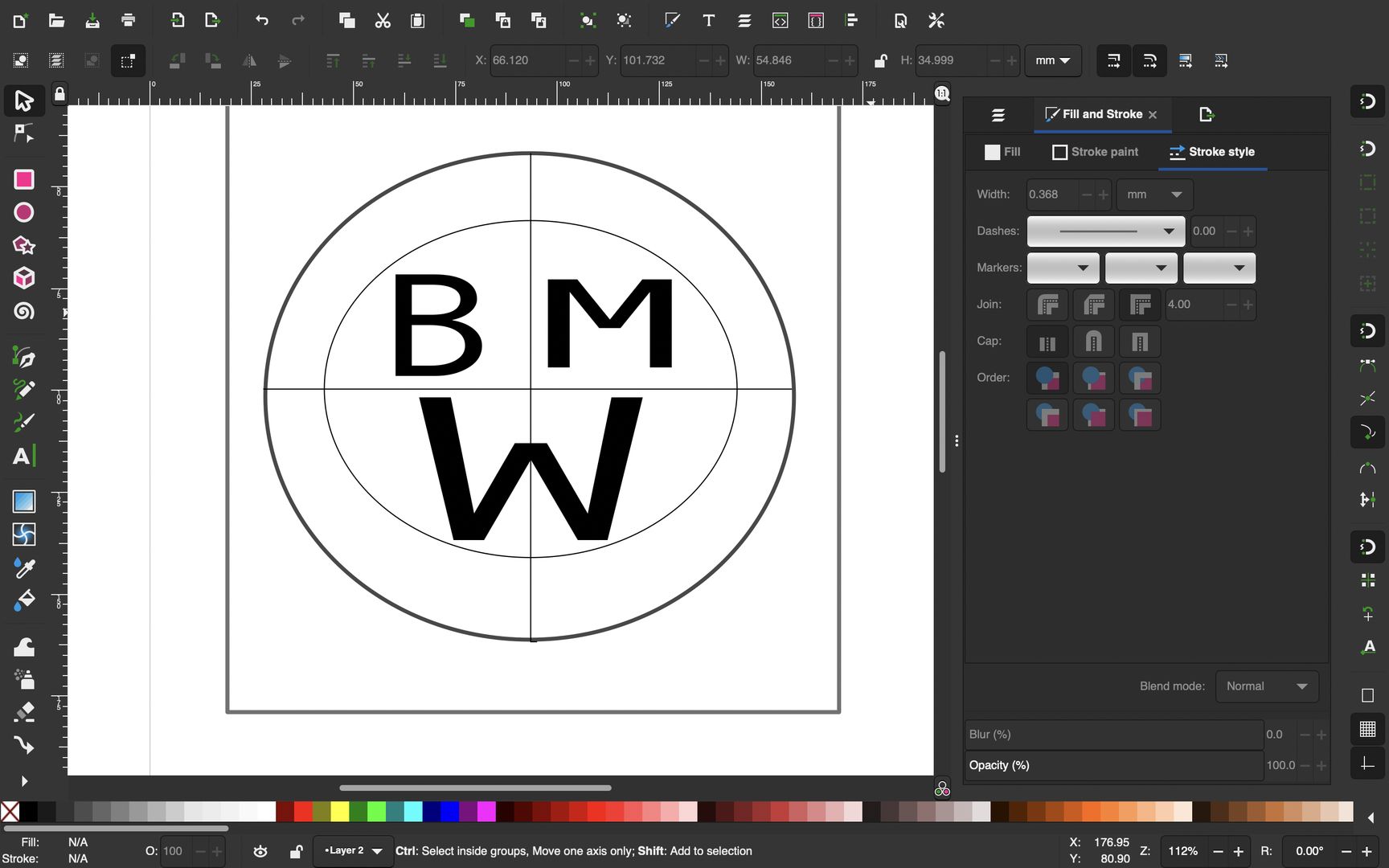

To create this sticker first I opened Inkscape and created a design as shown below.

I will be linking the tutorial for creating this design to the previous week for accessing that do checkout here.

Open Mods (which was was installed in Ubuntu)

Choose the png Image in “Read PNG”

Then click “calculate” at the top.

The open the teminal and use $dmesg command to check the usb driver for the Vinyl cutter.

Enter the USB driver name into the web socket section check the socket address.

And click send to printer.

The design will be cut if the vinyl cutting machine is set.

GROUP ASSIGNMENT

In this weeks group assignment we were divided into different groups and performed laser cutting using acrylic

Click this link to check the group assignment page.